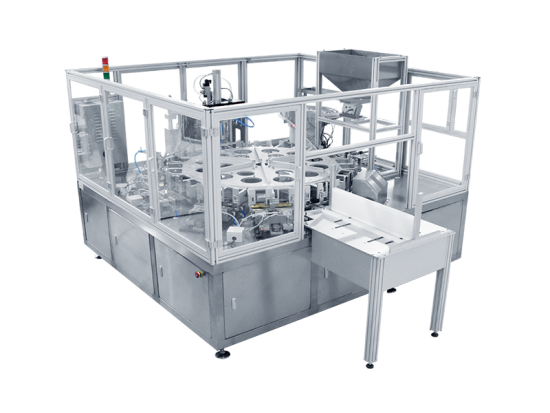

Technical Parameters

|

Item |

Technical Parameters |

|

Instrument size |

5800 mm x 4100 mm x 1800 mm (length*width*height) |

|

Pouches type |

Stand-up pouches, 3-side seal bags, gusset bags, shaped bags |

|

Material type |

Pouch:inner layer PE, inner layer PP |

|

Spout:PE, PP |

|

|

Product specifications |

Pouch length:150~350 mm(length),130~250 mm(width), spout sealing length: 60~120 mm |

|

Spout size: 10 mm, 14 mm,16 mm, etc |

|

|

Working speed |

|

|

Location precision |

≤0.5 mm |

|

Sealing blades |

Total 5 sets: 4 sets of heat seal, 1 set of cooling |

|

Temperature control module |

3 sets (8 channel module), Precision ±0.1℃ |

|

Heating Temperature |

0~300℃ |

|

Power |

380V/50Hz, 11KW |

|

Gas source |

0.6~0.8MPa, 2000L/H |

|

Weight |

3500 kg |

Product features

◆The equipment adopts a dual-channel linear mode, and the processes such as separate bags, corner cutting, install spout and heat sealing are fully automatic;

◆ PLC control and intelligent parameter setting, according to different bag types and spout to quickly set parameters, simple operation;

◆Adopted advanced temperature control module and SMC, Festo, AirTAC and other advantaged pneumatic components, reliable quality;

◆Adopted step-by-step heating and final cooling design, and the packaging effect is perfect;

◆ Automatic fault detection, alarm, stop, diagnosis and display of fault location;

◆The equipment is light in weight, occupies a small area and has stable performance;

◆The main components are all made of aluminum alloy and stainless steel, which meets the environmental health requirements of food and drug GMP.

System composition

◆The equipment adopts a dual-channel design and consists of a bag deliver system, a spout deliver system, a cutting system, a heat sealing system, a bag collecting system, central control system and base;

◆The bag deliver system consists of divide bags, location, deliver mechanism; The bag dividing mechanism separates bags individually, the deliver mechanism is responsible for delivery, and the location mechanism corrects the position;

◆Spout deliver system includes vibrating plate, linear vibrating deliver, rotating deliver spout mechanism; automatic detection and automatic control of start and stop.

◆The heat sealing system includes heat sealing and cooling, there are 4 sets of heat sealing blades and 1 set of cooling blade; Different specifications of heat sealing and cooling blades can be customized to adapt to the packaging of different specifications of spouts.

◆Each set of sealing blades has independent temperature control, which can set the temperature, operate and debug independently;

◆The bag collecting system conveys at a constant speed and automatically arranges the bags, which is convenient for product observation and inspection, and there is a reserved installation position for the coding machine.

◆The operation interface displays the working status in real time, such as the finished product quantity, date, servo motor parameters and cylinder action parameters, heat sealing time, etc

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar