Test principle

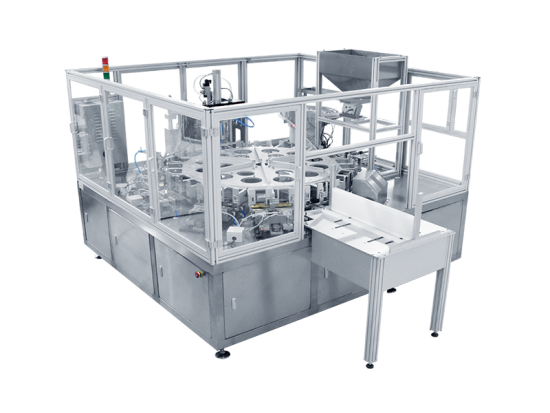

The plastic spout goes through the hopper and the vibrating deliver tray to the ready position, and is pushed by the plastic spout pushing mechanism to hang on the plastic spout holder and rotate with the rotating disc to the bag processing station. The bag to be processed is put on the bag fixture on the spout after taking the bag and turning it over (located directly above the spout holder). The spout and bag are moved together to the heat sealing station for heat sealing. The spout pouch that has been heat-sealed by the heat sealing blade is pushed by the launching mechanism to the finished bag station. The unqualified bags are automatically removed with the movement of the turntable to the unqualified bag station.

Technical Parameters

|

Item |

Technical Parameters |

|

Instrument size |

5800 mm x 4100 mm x 1800 mm (length*width*height) |

|

Pouches type |

Stand-up pouches, 3-side seal bags, gusset bags, shaped bags |

|

Material type |

Pouch:inner layer PE, inner layer PP |

|

Spout:PE, PP |

|

|

Product specifications |

Pouch length:150~350 mm(length),130~250 mm(width), spout sealing length: 60~120 mm |

|

Spout size: 10 mm, 14 mm,16 mm, etc |

|

|

Working speed |

80-90 pcs/min |

|

Location precision |

≤0.5 mm |

|

Sealing blades |

Total 5 sets: 4 sets of heat seal, 1 set of cooling |

|

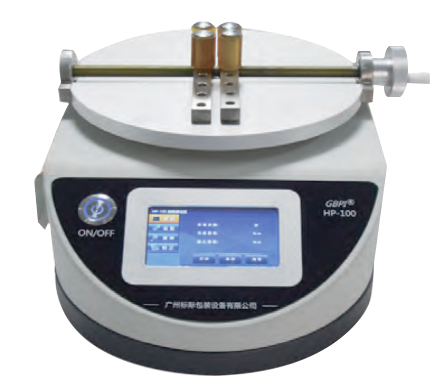

Temperature control module |

3 sets (8 channel module), Precision ±0.1℃ |

|

Heating Temperature |

0~300℃ |

|

Power |

380V/50Hz, 11KW |

|

Gas source |

0.6~0.8MPa, 2000L/H |

|

Weight |

3500 kg |

Product features

◆The equipment adopts a dual-channel linear mode, and the processes such as separate bags, corner cutting, install spout and heat sealing are fully automatic;

◆ PLC control and intelligent parameter setting, according to different bag types and spout to quickly set parameters, simple operation;

◆Adopted advanced temperature control module and SMC, Festo, AirTAC and other advantaged pneumatic components, reliable quality;

◆Adopted step-by-step heating and final cooling design, and the packaging effect is perfect;

◆ Automatic fault detection, alarm, stop, diagnosis and display of fault location;

◆The equipment is light in weight, occupies a small area and has stable performance;

◆The main components are all made of aluminum alloy and stainless steel, which meets the environmental health requirements of food and drug GMP.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar