Working principle

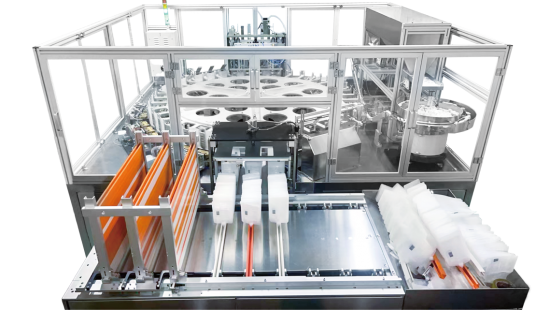

The conveyor belt transports the pouch to the pouch picking position. The pouch picking mechanism grabs the pouch and transports it to the pouch positioning platform for positioning. The pouch placing mechanism grabs the positioned pouch and transports it to the conveyor belt position. After the belt pressing mechanism presses the pouch, the conveyor belt transports the pouch to the cutting knife position for corner cutting, and then transports it to the opening position for opening and spout installation (after rotating 90 degrees, the cylinder pushes the nozzle forward), and then transports it to the sealing knife position for heat sealing, and finally cools it.

Technical Parameters

|

Items |

Technical Parameters |

|

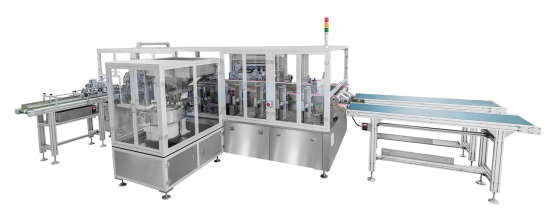

Device Dimensions |

5800 mm x 4100 mm x 1800 mm(Length x Width x Height) |

|

Packaging Type |

Stand-up pouches, 3-side seal pouches, gusset pouches, shaped pouches (customized) |

|

Material Type Product Specifications |

Pouch: Inner layer PE, inner layer PP |

|

Spout: PE, PP |

|

|

Operating Speed Bevel Sealing Angle |

Pouch length: 150~350 mm (length), 130~250 mm (width), sealing length: 60~120 mm |

|

Spout size: 8.5 mm (conventional), 10 mm, 14 mm, 16 mm, etc. |

|

|

Positioning Accuracy |

80~90 pieces/minute, single channel 40~45 pieces/minute (depending on different materials and bag sizes) |

|

Packaging Tool |

45°±5°(Other angles can be customized) |

|

Temperature Control Module |

≤±0.5 mm |

|

Heating Temperature |

There are 6 groups in total, including 1 preheating group, 4 heat sealing groups, and 1 cooling group |

|

Power Supply |

3 groups (8-channel modules), accuracy ±0.1°C |

|

Air Source |

0~300℃ |

|

Weight |

380V/50Hz,13KW |

|

Project |

0.6~0.8MPa,22L/min |

|

Device Dimensions |

3500 kg |

Product features

u The equipment adopts dual-channel mode, and the processes such as pouchging, corner cutting, tube loading and heat sealing are fully automatic;

u PLC control and intelligent parameter setting are adopted, and parameters can be quickly set according to different pouch types and straws, and the operation is simple;

u Imported temperature control modules and pneumatic components such as SMC, Festo, and AirTac are adopted, with reliable quality;

u The packaging step design of step-by-step heating and final cooling is adopted, and the packaging effect is excellent;

u Automatic fault detection, automatic alarm, automatic stop, automatic diagnosis and display of fault location;

u The equipment is light in weight, small in footprint and stable in performance;

u All main components are made of aluminum alloy and stainless steel, which meet the environmental hygiene requirements of food and drug GMP.

System composition

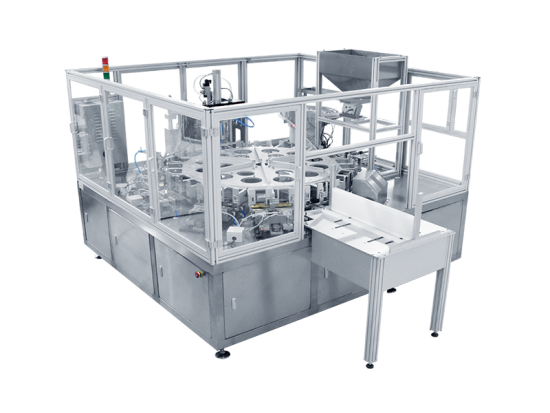

❀The equipment features a dual-channel design and consists of a bag feeding system, a tube feeding system, a cutting mechanism, a heat sealing system, a bag collection system, a control system, and a machine base.

❀The bag feeding system consists of a bag separating mechanism, a positioning mechanism, and a transport mechanism. The bag separating mechanism separates finished bags individually, the transport mechanism transports them, and the positioning mechanism adjusts their position.

❀The tube feeding system includes a vibrating plate, a linear vibrating feeder, and a rotary tube loading mechanism. The loading process is automatically monitored and automatically controlled.

❀The heat sealing system includes heat sealing and cooling, with five sets of heat sealing blades and one set of cooling blades. Custom heat sealing and cooling blades of varying specifications can be customized to accommodate different straw sizes.

❀Each set of sealing blades has independent temperature control, allowing for independent temperature settings and independent operation and debugging.

❀The bag collection system delivers bags at a constant speed and automatically arranges bags for easy product observation and inspection.

The user interface displays real-time operating status, including production speed, number of finished products, team output, date, and temperature.

Application areas

|

|

|

|

Laundry detergent stand-up pouch |

Seasoning stand up pouch |

|

|

|

|

Beverage pouch |

Folding water pouch |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar