Test principle

Adhere the cellophane tape that meets the standards and the printed surface of the treated sample ink with the standard load, rolling speed and rolling times, and then peel them off with a certain pressure and peeling speed after placing them for a certain period of time. Open, observe and measure the situation that the ink layer of the sample is peeled off, so as to judge and analyze the bonding fastness of the printed ink layer.

GBT 7706, GB/T 7707, JIS C2107, JIS Z0237

Specification

|

Item |

Technical Parameters |

|

Rolling speed |

0~600 mm/min |

|

Rolling load |

20N±.5N |

|

Roll times |

1~999999 times |

|

Roller diameter |

84mm |

|

Roller width |

45mm |

|

Dimension |

440mm×400mm×200mm |

|

Power |

350 W |

|

Weight |

20kg |

|

Power supply |

AC220V, 50Hz |

Application

|

Plastic printing materials |

It is suitable for testing the bonding fastness of printing ink layers on plastic film and cellophane decorative printed matter (including composite film printed products) produced by gravure printing process. |

Fiatures

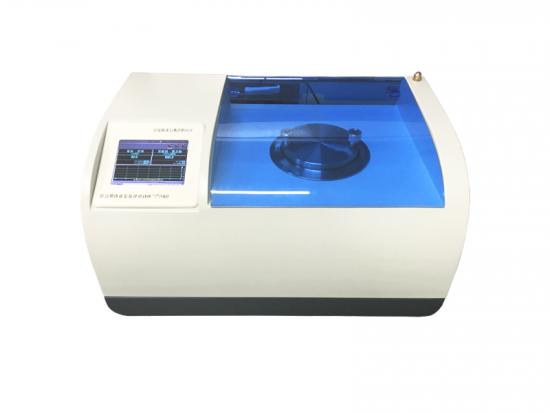

Ø The host is equipped with a color touch screen, which is convenient for users to carry out test operations. Fully automatic operation, one-button operation, automatic shutdown, simple and convenient operation.

Ø Using high-precision ball screw parts, the operation is stable, the test machine has a long life, good long-term stability and energy saving. The running speed and running times can be changed freely to meet the requirements of different standards.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar