Introduction

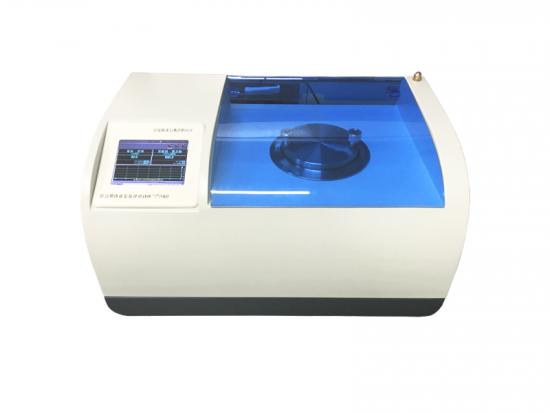

This product adopts the radial self-expanding sealing structure with independent intellectual property rights of our company; the operation, control and display of the touch LCD screen are used, and the digital program control is realized in the state of man-machine dialogue through the microcomputer system; the equipment is equipped with a printer and a USB Interface, real-time printing and recording of key parameters of sterilization; equipped with back pressure and spraying device, which can effectively prevent the package from bursting and quickly cool down, and the cover is equipped with a pneumatic spring rod, which is convenient to open the cover.

Specification

|

Item |

Technical parameters |

|

Volume |

100L |

|

Sterilization temperature |

Roomtemperature 105℃-134℃ |

|

Holding time |

1-999min |

|

Overpressure release pressure |

0.23MPa (Safety valve relief) |

|

Water for sterilization |

Medical distilled water |

|

Space size |

100L: φ388×780 |

|

MachineWeight |

70kg/50L,82kg/75L,95kg/100L |

|

Gas delivery pressure |

≥0.18MPa and≤0.20MPa |

|

Water pressure for spraying and filling |

≥0.22MPa |

|

use environment |

Altitude: ≤2000m;Ambient temperature: 5-40℃ Relative humidity: ≤85%;Atmospheric pressure:70kpa-106kpa Atmospheric pressure: 70kpa-106kpa Ambient temperature:5-40℃; Relative humidity: ≤85%; Atmospheric pressure: 70kpa -106kpa; |

|

Maximum power (while warming up) |

100L/4kVA |

|

Safe temperature control |

Set temperature +2℃ (Stop heating, sound and message prompt) |

|

Power supply |

AC 220V/50HZ |

Features

a The container components of this product and the parts in contact with the sterilized material are all made of high-quality stainless steel materials, which are made by forming, argon arc welding, polishing and other processes, and have the advantages of corrosion resistance and long service life.

b The design and manufacture of the product body, cover and safety accessories all meet the requirements of TSG21-2016 "Safety Technical Supervision Regulations for Stationary Pressure Vessels" and NB/T47052-2016 "Simple Pressure Vessels".

c The radial self-expanding sealing structure used in this product is a technology with independent intellectual property rights of the company, and the sealing ring is molded with silicone rubber.

d The product has a device for internal cooling of process exhaust steam to prevent high-temperature steam from affecting the environment.

e Using microcomputer control technology, a touch-type LCD screen is used to form a good interface for man-machine dialogue, and the operating procedures and running conditions are dynamically displayed on the LCD screen.

f The cooking pot has a custom program, and the user can set the sterilization temperature and holding time on the monitoring interface of the touch screen according to different sterilization objects, and the program will be automatically memorized after setting.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar