1. Introduction

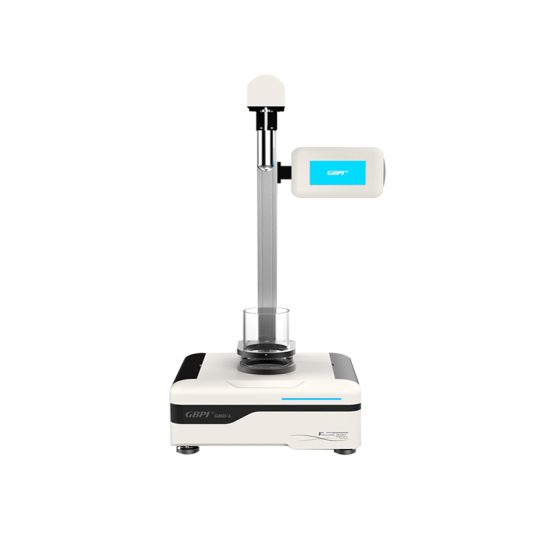

GBD-L2 falling dart impact tester is suitable for testing materials such as plastic film or sheet and steel plate coating with a thickness of less than 1mm. Under a given height of free falling dart impact, it can measure the energy (in Quality to express results) of plastic films,thin section specimens and other materials. Through the impact resistance test, it can prevent the packaging surface from being damaged when the packaging material is impacted or dropped due to insufficient toughness of the packaging material, and effectively avoid the product from being damaged due to impact or falling in the circulation link. It can be used in scientific research, teaching, industrial and mining enterprises, laboratories, research institutes and quality supervision departments.

2. Feature

The host is equipped with a color touch screen, which is convenient for users to perform test operations.

The novel mechanical model and the humanized design of the operation interface make the operation of the instrument simple and convenient;

Test method A method, B method, single-chip test mode design, one machine with three uses;

Using the principle of electromagnetic suction, it can be released automatically, effectively avoiding system errors caused by human factors

The test process is intelligent, which greatly improves work efficiency;

The sample is pneumatically clamped and released, which reduces the error and test time;

No need for manual drawing and marking in the test process, and the data parameter system LCD display;

The test data system automatically recognizes and calculates without manual intervention;

Built-in printer, which can print test reports.

The instrument can perform data query, query the results of each group of data, and can support 30 groups of data queries.u

3. Standard

ISO7765-1、GB/T 9639、GB/T 15267、ASTM D1709、JIS K7124

4. Technical Parameter

|

Item |

Technical Parameter |

|

Test Method |

Method A, Method B, Single Chip Test |

|

Method A Test Range |

50~2000g |

|

Method B Test Range |

300~2000g |

|

Single Chip Test Range |

20g、25g、40g、60g、80g |

|

Test Accuracy |

0.1g |

|

Dart Head Size |

A methodΦ38±1mm,B methodΦ50±1mm |

|

Weight |

A 5g,15g,30g,80g each 8 pcs,120g 16 pcs(A method) B 15g,45g,90g each 8 pcs,180g 9 pcs(B method)

|

|

Weight size |

A methodΦ30mm,B methodΦ45mm |

|

Impact height |

1500mm/660mm |

|

Specimen fixture |

Pneumatic fixture,Outer diameter150mm,Inside diameter125mm |

|

Gas source |

Compressed air,0.6~0.8MPa |

|

Air connection |

Air source interface,Φ6mm tube |

|

Dimensions |

510*440*1300mm |

|

Weight |

50kg |

|

Power supply |

AC 220V,50Hz |

|

Power |

75W |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar