- Universal Single-column Electronic Tensile Testing Machine GBL-H2Product Brief The GBL-H2 Universal Single-column Electronic Tensile Testing Machine is a mechanical property testing instrument independently developed and manufactured by Guangzhou GBPI R&D team, in compliance with the requirements of standards such as GB and ASTM as well as market demands. Equipped with high-precision sensors, the instrument features high force measurement accuracy, stable loading, and long service life. The LCD screen, integrated with professional software, displays test curve data in real time and supports test report query, ensuring convenient and efficient testing. With fully automatic operation and control of the measurement unit, it is furnished with comprehensive safety protection functions including limit protection, overload protection, and emergency stop. Suitable for mechanical property tests such as tension, peeling, heat sealing, tearing, and puncturing of various metal and non-metal materials, the instrument meets the test technology requirements of national technical supervision departments. It is widely applied in quality control of plastic film, food, and pharmaceutical manufacturers, as well as scientific research and teaching experiments in testing institutions and schools. Test Principle Fix the treated sample between the two chucks of the fixture, and start the instrument to make the two chucks move relatively. The force sensor installed on the movable chuck collects the force changes during the test, while the built-in displacement sensor of the machine captures the displacement changes, so as to calculate the performance indicators of the sample such as tension, peeling, heat sealing, and tearing. Tensile test principle diagram Standard GB 8808、GB 13022、GB/T 1040、GB 4850、GB/T 7753、GB/T 7754、GB/T 453、GB/T 17200、GB/T 16578.1、QB/T 1130、GB/T 2791、GB/T 2790、GB/T 2792、GB/T 7122、GB/T 10004、GB/T 17590、JJG 139、GB/T 6344、GB 10808、YBB 00112003、YBB 00102003、YBB 00132002、YBB 00202004、ASTM D828、ASTM E4、ASTM D882、 ASTM D1938、ASTM D3330、ASTM F904、JIS P8113、QB/T 2358 Specifications Item Technical Parameters Force Measurement Range 0~300 N (0~500 N optional) Force Measurement Accuracy Within ±0.5 %FS of indicated value (Class 0.5) Test Speed 0~500 mm/min (stepless speed regulation) Displacement Precision Within ±0.5% of indicated value Effective Test Width 30 mm (50 mm, 60 mm customizable) Effective Test Stroke 750 mm (1000 mm, 1200 mm customizable) Dimension (L×W×H) 600 mm×500 mm×1300 mm Weight 65 kg Power Supply AC 220 V, 50 Hz Application Plastic film It is suitable for tensile, peeling, heat sealing, tearing, puncturing, compression, bending and other performance tests of plastic films, composite materials, flexible packaging materials, tapes and other products. Composite film bag It is suitable for tensile, peeling, heat sealing, tearing, puncture, compression, bending and other performance tests of composite films, co-extruded films, composite bags, retort bags, aluminum-plastic composite bags and other products. Paper It is suitable for tensile strength, peeling, deformation, tearing, heat sealing, bonding and other performance tests of paper, kraft paper, facial tissue, toilet paper and other products. Medical Patches It is suitable for tensile strength, peeling, deformation, tearing, heat sealing, bonding and other performance tests of medical cold compress, plaster and other products. Pressure Sensitive Tapes It is suitable for tensile strength, peeling, deformation, tearing, heat sealing, bonding and other performance tests of cellophane tape, electrical insulating tape, medical zinc oxide adhesive tape and other products. Product Features Elegant, Compact and User-friendly Machine Design Desktop column structure with an elegant and compact appearance, enabling seated operation for maximum comfort. Flexible, Versatile and Efficient Testing Methods Capable of conducting tests including tension, peeling, heat sealing, tearing, and puncturing; supports multi-parameter setting such as width, speed, thickness, and chuck spacing. High sampling rate (100 times/second) ensures accurate and reliable test data. Safe and High-end Mechanical Structure Three-level safety protection; equipped with an emergency stop switch for guaranteed safety; adopts imported core components for high precision and long service life; LCD screen displays test data and working status in real time. Intelligent Operating System Supports user management, permission management and audit trail, complying with the requirements of Annex to GMP <Computerized Systems>. Flexible setting of test process parameters meets the requirements of non-standard tests and scientific research tests. Allows standalone testing without a computer with automatic data processing; built-in micro-printer enables real-time data printing. The instrument is also equipped with a computer interface for online testing via PC connection. Laboratory Intelligent IoT Platform (Optional) Supports access to the laboratory intelligent IoT platform, realizing functions such as test data management and remote fault diagnosis and troubleshooting.

- tensile tester

- plastic tensile tester

- plastic film tensile tester

- peel seal tester

- tensile/peel/seal strength/tear tester

Tags :

- W416 2.0 Water Vapor Transmission Rate TesterProduct Profile • The W416 2.0 Infrared Method Water Vapor Transmission Rate Tester is a high-end precision testing instrument for packaging materials, newly developed and upgraded by Guangzhou Standard International R&D Team in full compliance with the requirements of **GB/T 26253** and **ASTM F1249** standards as well as market demands. • Based on the testing principle of infrared moisture analysis sensors, it provides wide-range, high-efficiency water vapor transmission rate (WVTR) testing for high, medium and low barrier materials. • It is suitable for testing the water vapor transmission performance of films, sheets, papers, packages and other related materials in industries such as food, pharmaceuticals, medical devices, daily chemicals, photovoltaic electronics, etc. • It is an ideal offline or online configuration instrument for manufacturers in the packaging industry to test the barrier performance of packaging materials. Testing Principle The W416 2.0 Water Vapor Transmission Rate Tester adopts the infrared method principle: 1. Fix the pre-treated sample in the middle of the test chamber, dividing the chamber into a high-humidity chamber and a low-humidity chamber. 2. Compressed air flows through the high-humidity chamber, while dry nitrogen (carrier gas) flows through the low-humidity chamber at a constant flow rate. 3. Due to the humidity gradient, water vapor penetrates from the high-humidity chamber to the low-humidity chamber. 4. The water vapor passing through the sample is carried to the infrared sensor by the flowing dry nitrogen. 5. Parameters such as the sample’s water vapor transmission rate are derived from the electrical signal output by the sensor. Working Principle Diagram of Infrared Method Standards • ISO 15106-2 • ISO 21760-1 • ASTM F1249 • GB/T 26253 • JIS K7129-2 • Chinese Pharmacopoeia 2025 Edition <4010 Determination of Water Vapor Transmission Rate of Pharmaceutical Packaging Materials> • YBB 00092003 Technical Parameters Item Technical Parameter Test Range 0.002 ~ 100 g/(m²·24h) Repeatability The greater value between 0.005 or 2% Resolution 0.0001 g/(m²·24h) Temperature Control Range 15 ~ 45℃ Temperature Control Precision ±0.1℃ Humidity Control Range (5 ~ 90)%RH, 100%RH Humidity Control Precision ±1%RH Test Area 50.24 cm² Sample Size Φ100 mm Sample Thickness ≤ 3 mm Sample Quantity 6 pieces Carrier Gas 99.999% Nitrogen (provided by the user) Carrier Gas Pressure ≥ 0.1 MPa Carrier Gas Flow Rate 5 ~ 100 mL/min Pneumatic Pressure ≥ 0.3 MPa Dimension 1140mm × 600mm × 440mm Weight 55 kg Power 750 W Power Supply AC 220 V, 50 Hz

- Water vapor permeability tester

- moisture vapour transmission rate

- water moisture tester

- packaging lab equipment

- barrier film water vapor permeability analyzer

- water vapor transmission rate tester

Tags :

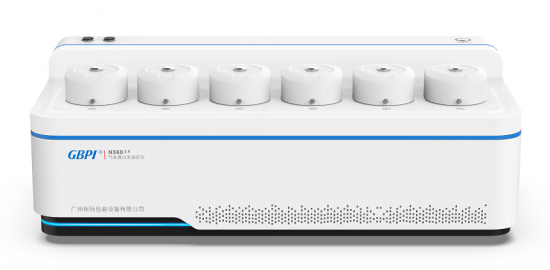

- Gas Transmission Rate Tester for Packaging FilmIntroduction The N560 2.0 Gas Transmission Rate Tester is a high-precision laboratory testing equipment integrating machinery, electronics and software. It is suitable for the gas barrier property test of plastic films, composite films, sheets, metal foils and other sheet materials, as well as the gas transmission rate test of packaging containers such as bottles, bags, cans and boxes made of plastics, rubber, paper and other multi-type materials.View More

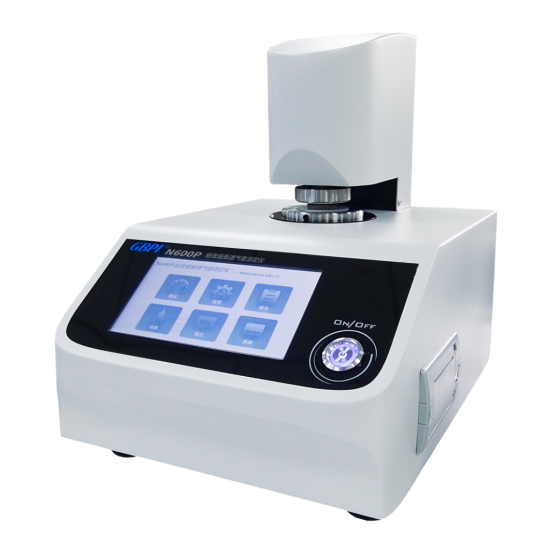

- Paper & Paperboard Air Permeability TesterProduct Brief The N600P Paper & Paperboard Air Permeability Tester is custom-developed to align with standards like GB/T 458-2008 and ISO 5636. It adopts the differential pressure method as its core testing principle, and innovatively integrates three industry-common testing approaches (Gurley, Schopper, and Bendtsen) into a single device. This tester is applicable to air permeability detection of various paper and paperboard materials, and can measure key indicators including: material air permeability, air resistance, gas transmission rate, and total gas transmission volume. Testing Principle Gurley Method Under a constant differential pressure of 1.23 kPa, measure the time required for 100 mL of gas to pass through the sample. Schopper Method Select a suitable test duration under a constant differential pressure (1.00 kPa±0.01 kPa or 2.50±0.01 kPa), and calculate the gas flow rate through the sample by measuring the gas volume. Bendtsen Method After clamping the sample for 5 seconds under a constant differential pressure of 1.47 kPa, test the gas flow rate through the surface of the sample. Executed Standards GB/T 458-2008, SJ/T 10171-2016, ISO 5636-5:2003, ISO 5636-2:1984, ISO 5636-3:2013, TAPPI T460 Technical Parameters Item Technical Parameters Test Range 0.1~10 μm/(Pa·s) Resolution 0.001 μm/(Pa·s) Differential Pressure Range 0~5 kPa Pressure Resolution 0.001 kPa Test Area 6.42 cm² or 10.0 cm² Sample Size >50 mm×50 mm Instrument Dimensions (L×W×H) 450 mm×400 mm×300 mm Power 100 W Power Supply 110~250 VAC, 50~60 HzView More

- Battery Separator Air Permeability TesterProduct Brief The N600E Battery Separator Air Permeability Tester is designed and developed in accordance with standards such as GB/T 36363-2018. Adopting the differential pressure method as its testing principle, it is professionally used for testing the air permeability of battery separators, breathable films, and related polymer materials. Testing Principle In an environment with controlled temperature, humidity, and normal pressure, the tester measures the time required for 100 mL of air to pass through a 6.45 cm² separator under an applied pressure of 1.21 kPa. Executed Standards GB/T 36363-2018, ISO 5636-5:2003, TAPPI T460 Technical Parameters Item Technical Parameters Test Range 60~12000 sec/100mL Resolution 0.1 sec/100mL Pressure Range 0~5 kPa Pressure Resolution 0.001 kPa Test Area 6.45 cm² Sample Size >50 mm×50 mm Instrument Dimensions 450 mm×400 mm×300 mm Power 100 W Power Supply 110~250 VAC, 50~60 Hz Product Features • The instrument's differential pressure is adjustable within the range of 0~5 kPa, with a precision of 0.001 kPa, fully meeting the test pressure requirements of different methods;• Supports multi-unit display (s/100mL and μm/(Pa·s));• The test range can be customized according to different sample requirements;• Excellent airtightness;• Arbitrary pressure adjustment, fully automatic operation, and automatic measurement and calculation of results;• Equipped with a color touch screen, no external computer required, enabling real-time observation of sample air permeability;• Built-in micro-printer for real-time printing of test reports;• The upper computer software is designed in accordance with the new GMP Appendix "Computerized Systems", supporting functions such as hierarchical permission management, audit trail, and electronic signature (optional).View More

- Carbon Paper Air Permeability Rate TesterProduct Brief The N600C Carbon Paper Air Permeability Rate Tester is designed and developed in accordance with GB/T 20042.7-2014. Adopting the differential pressure method as its testing principle, it is professionally used for measuring the air permeability rate of various types of carbon paper for proton exchange membrane fuel cells (PEMFC). Testing Principle Based on the differential pressure method, the sample is placed between two fixtures, forming a constant differential pressure on both sides of the sample. Driven by the differential pressure, gas flows from the high-pressure side through the sample to the low-pressure side. The air permeability rate of the carbon paper is calculated based on the transmission flow rate, sample thickness, test area, and test differential pressure. Executed Standards GB/T 20042.7-2014 Technical Parameters Item Technical Parameters Test Range 0~200,000 mL·mm/(cm²·h·mmHg)0~14,701 mL·mm/(cm²·hr·mmAq) Resolution 0.1 mL·mm/(cm²·h·mmHg)0.1 mL·mm/(cm²·hr·mmAq) Pressure Range 0~500 Pa (other ranges available upon request) Pressure Resolution 0.1 Pa Pressure Accuracy 0.1% FS (Full Scale) Flow Range 0~50 L/min (other ranges available upon request) Flow Resolution 1 mL/min Flow Accuracy 1% FS (Full Scale) Test Area 16 cm² Instrument Dimensions 410 mm×295 mm×365 mm Power 100 W Power Supply 110~250 VAC, 50~60 Hz Product Features • The instrument's differential pressure is adjustable within the range of 0~500 Pa, with an accuracy of 0.1% FS, fully meeting the test pressure requirements of different samples;• The test range can be customized according to different sample requirements;• Arbitrary pressure adjustment, fully automatic operation, and automatic measurement and calculation of results;• Equipped with a color touch screen, no external computer required;• Built-in micro-printer for real-time printing of test reports;• The upper computer software is designed in accordance with the new GMP Appendix "Computerized Systems", supporting functions such as hierarchical permission management, audit trail, and electronic signature (optional).View More

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar