Introduction

AUTO GBM-L2 Dual-Pressure Methods Vacuum Decay Leak Detection Tester adopts the test principle of vacuum decay method/pressure decay to detect micro-leakage of finished packaging. It can be applied to packaging systems composed of vials, ampoules, Leakage detection of pre-filled needles, eye drop bottles, HDPE bottles, infusion bottles/bags and other pharmaceutical packaging, food packaging, and chemical industry packaging.

Test principle

The host is connected to a sealed test chamber customized according to the sample. When performing the vacuum decay method test, the instrument evacuates the test chamber, and a pressure difference is formed inside and outside the sample. Under the action of the pressure, the gas/liquid in the sample enters the test chamber through the leak hole. The main engine uses the absolute pressure sensor and the differential pressure sensor to monitor the pressure change in the chamber to judge whether the sample leaks. When performing the pressure decay method test, the instrument fills the test chamber with a predetermined air pressure, and the gas in the test chamber enters the sample through the leak hole. The host uses absolute pressure sensors and differential pressure sensors to monitor the pressure changes in the chamber to determine whether the sample is leaking.

Standard

ASTM F2338-2009(2013), YY-T 0681.18-2020, USP<1207.2>, ASTM F2095

Specification

| Item | Parameters |

|---|---|

| Absolute Pressure Testing Range | (0 - 300) kPa |

| Differential Pressure Testing Range | (-2 - 2) kPa |

| Detection Sensitivity | 1 - 3 μm |

| Balancing/Testing Time | 1 - 3600 s |

| Vacuum Purge Time | 1 - 3600 s |

| Set Flow Rate | 0 - 3 mL/min |

| Testing System | Dual Sensor Technology/Dual Cycle Testing |

| Testing Chamber | Customized according to the sample |

| Applicable Products | Vials, Ampoules, Prefilled Syringes, Infusion Bottles/Bags, etc. |

| Detection Principle | Vacuum Decay Method/Pressure Decay Method |

| Dimensions of the Main Unit | 495 mm455 mm280 mm |

| Ambient Temperature | 20℃ - 25℃ |

| Relative Humidity | 40% - 60% |

| Working Power Supply | AC 220V, 50HZ |

Features

u Dual-Pressure Methods, to help solve testing difficulties

The double combination of vacuum decay method and pressure decay method solves the problem of easy misjudgment and false negative for freeze-dried powder injections containing vacuum in the bottle using a single vacuum decay method.

Based on dual-sensor and dual-circulation system technology, high-quality absolute pressure sensor and differential pressure sensor, with an accuracy of 0.1% FS, can effectively detect large and small leaks, accurately calculate the leak hole diameter, and give a pass or fail judgment.

The instrument has low sensitivity and good test repeatability

For rigid samples, the detection sensitivity is as low as 1 μm, and the test repeatability is as low as 0.8%. The instrument has stable performance, low noise and good repeatability.

u Imported brand accessories, excellent performance

Imported brand vacuum pump, pumping rate up to 3 L/s, noise as low as 50 DB, high ultimate vacuum, convenient oil level detection and replacement.

The imported gas mass flow controller can simulate micro-leaks arbitrarily, with a resolution of 0.001 mL/min, which provides a reliable guarantee for the method verification of instrument sensitivity.

u Large size touch screen, intelligent operation

Color 7-inch touch screen, clear view, sensitive touch, easy to operate.

Equipped with a micro-printer, USB data interface, and supports PC software measurement and control operation.

The test software is designed according to the GMP appendix "Computerized System". It has an audit trail function and multi-level authority settings for users, which can meet the needs of the pharmaceutical industry for data traceability.

u Personalized customization to meet the needs of different samples

For different test samples, it supports customization of suitable test chambers to meet the needs of different tests.

For the same type of samples, it supports customized nesting mode, which can realize the sharing of a test chamber for samples of various specifications.

Application

|

|

|

|

|

Freeze-dried powder injection |

Injection |

Prefill needle |

|

|

|

|

|

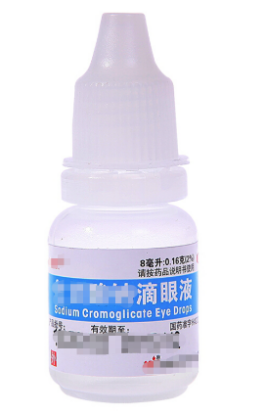

Eye drops |

Plastic Ampoule BFS |

Infusion bags |

Factory configuration

|

Standard |

Host machine, vacuum pump, test chamber and 3 sets of yin and yang control (customized as required), 11-inch touch panel, professional software (GMP) |

|

Optional |

Imported gas flow meters, air compressors, printers, calibration certificates |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar