Standard

GJB 150.3 high temperature test GJB 150.4 low temperature test

IEC68-2-1 Test A: Cold IEC68-2-2 Test B: Dry Heat

GB 11158 "Technical Conditions for High Temperature Test Chambers" GB10586-1 "Technical Conditions for Humidity and Heat Test Chambers"

GB/T 2423.2 "Basic Environmental Test Procedures for Electrical and Electronic Products Test B: High Temperature Test Method"

GB/T 2423.3 "Basic Environmental Test Procedures for Electrical and Electronic Products Test Ca: Constant Damp Heat Test Method", etc...

Technical Parameters

|

Internal dimensions |

W500*H600*D500mm |

|

External dimensions |

W780*H1720*D1490mm The actual product shall prevail; |

|

Temperature range |

-40℃~150℃ |

|

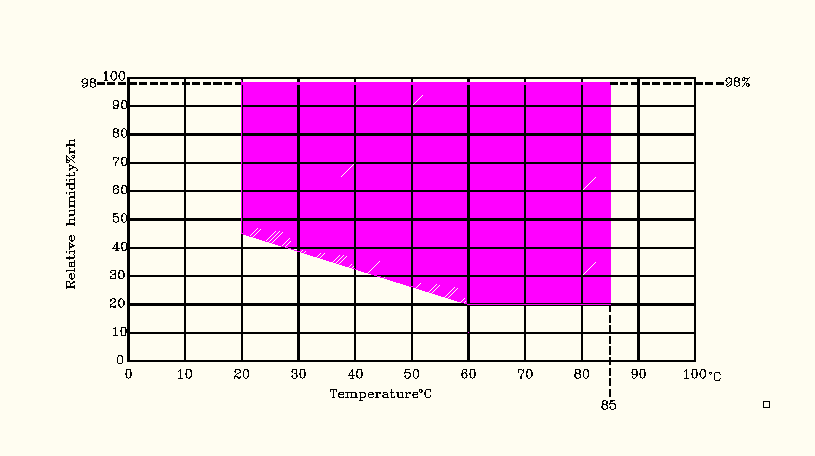

Humidity range |

20%~98%R.H (Refer to the temperature and humidity control range chart) |

|

Internal material |

SUS304 Stainless steel |

|

External material |

Electrostatic spray paint or SUS304 stainless steel |

|

Cooling System |

French Taikang single stage compressor |

|

Refrigerant |

R404a(DuPont, USA) |

|

Cooling method |

Air-cooled |

|

Controller |

Self-developed 7-inch full-color touch screen controller |

|

Heating rate |

2.0℃~4.0℃/min Non-linear no-load |

|

Cooling rate |

0.7℃~1.0℃/min Non-linear no-load |

|

Appendix |

50mm wiring hole*1 set, humidifying gauze*1 pack, manual warranty card*1 copy, storage rack*2 pieces |

|

Weight(kg) |

160 |

|

Voltage(V) |

AC220V |

|

Installed power(kw) |

5(Operating power 3.5KW) |

|

Maximum current(A) |

22 |

Specification

|

1. Application |

Equipment used to test the performance of materials in various environments and test the heat resistance, cold resistance, dry resistance and humidity resistance of various materials. It is suitable for quality testing of products such as electronics, electrical appliances, mobile phones, communications, instruments, vehicles, plastic products, metals, food, chemicals, building materials, medical care, and aerospace. |

|

2. Sample limit |

This test equipment prohibits: testing of flammable, explosive and volatile substance samples or storage of corrosive substance samples or storage of biological samples, testing or storage of strong electromagnetic emission source samples |

|

3. Performance |

|

|

3.1.Test environment conditions 3.1. Test Methods |

The ambient temperature is +25°C, the relative humidity is ≤85%, and there is no sample in the test chamber GB/T 5170.2 Temperature test equipment GB/T 5170.5 damp heat test equipment (only damp heat type) |

|

3.2. Temperature fluctuation |

±0.5℃ |

|

3.3. Temperature deviation |

±2.0℃ |

|

3.4. Humidity fluctuations |

±2.5%R.H |

|

3.5. Humidity Deviation |

±3.0% |

|

3.6. load condition |

The test space is no more than three-quarters of the total space, and there is no heat source. |

|

3.7. Punching sample holder (reference picture) |

|

|

3.8. Temperature and humidity control reference chart |

|

|

3.9. Meet the test standard

|

GJB 150.3 high temperature test GJB 150.4 low temperature test IEC68-2-1 Test A: Cold IEC68-2-2 Test B: Dry Heat GB 11158 "Technical Conditions for High Temperature Test Chambers" GB10586-1 "Technical Conditions for Humidity and Heat Test Chambers" GB/T 2423.2 "Basic Environmental Test Procedures for Electrical and Electronic Products Test B: High Temperature Test Method" GB/T 2423.3 "Basic Environmental Test Procedures for Electrical and Electronic Products Test Ca: Constant Damp Heat Test Method", etc... |

|

4. Structure |

|

|

4.1. Insulation layer structure

|

Outer wall material: electrostatic spray paint or 304 stainless steel Inner wall material: 304 stainless steel Box insulation material: flame retardant and fireproof rigid polyurethane foam Door insulation material: flame retardant and fireproof rigid PU polyurethane foam |

|

4.1. air conditioning channel |

Up and down air outlet, centrifugal circulation motor |

|

4.2. Test box standard configuration |

The visible window area is about L220xH250mm with three vacuum layers; Lighting lamp in the box, wiring lead hole: 1 set of φ50mm; |

|

4.3. Door |

Single door, left door, observation window, lighting, window/door frame anti-condensation electric heating device; |

|

4.4. Control Panel |

Controller display, running indicator light, power button switch, USB data download interface |

|

4.5. mechanical room |

Refrigeration unit, water tray, drain hole, etc. |

|

4.6. Power distribution control cabinet |

Power distribution board, cooling system |

|

4.7. Heater |

High-temperature insulating ceramic heating wire (fast heating speed, small inertia, etc.) |

|

4.8. Humidifier |

Steam humidification system, circulation through the air duct system |

|

4.9. Power cord hole and drain hole |

located on the back of the device |

|

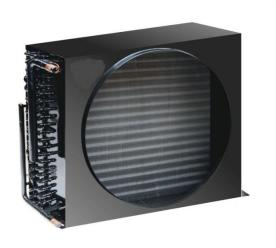

5. Cooling System |

|

|

6.1 Refrigeration Compressors |

|

|

6.2 Evaporator |

|

|

6.3Condenser |

|

|

6.4 Expansion system |

Volume Control Refrigeration Systems (Capillary or Expansion Valve) |

|

6.6 Chiller control method |

The controller of the control system automatically adjusts the operating conditions of the refrigerator and the evaporation pressure regulating valve according to the test conditions. Compressor return air cooling circuit. |

|

6.7 Refrigerant |

American DuPont R404a (environmentally friendly, ozone depletion index is 0)

|

|

7.Screen controller |

Zhenghang independent research and development program (hardware customization) |

|

7.1 Features of temperature and humidity controller |

Zhenghang independently developed a 7-inch touch screen control system, Chinese and English operation interface, with 110 groups of programs and 5000 segments of memory, Each section is 999Hour59Min, which can be divided and set arbitrarily and has multiple sets of PID control functions. |

|

7.2 Controller Specifications |

Accuracy: temperature ±0.01℃+1digit, humidity ±0.1%R.H+1digit Resolution: temperature ±0.01℃, humidity ±0.1%R.H. Temperature slope: 0.1 ~ 9.9 can be set. With upper and lower limit standby and alarm function. Temperature and humidity input signal wet and dry bulb PT100x2. 15 groups of P.I.D control parameter settings, P.I.D automatic calculation. Dry and wet bulb automatic correction. |

|

7.3 Screen display function introduction

|

Temperature and humidity setting (SV) and actual (PV) values are directly displayed. It can display the current program number, segment, remaining time and cycle times. Running cumulative time function. The set value of the temperature and humidity program is displayed as a graphic curve, and it has the function of real-time display of the program curve execution. It has a separate program editing screen, and each page can input at least 5 segments of temperature, humidity and time. Chinese and English can be switched at will. The fault prompt screen is displayed. The screen can be adjusted for backlight. The screen display protection function can be set as timing, TIMER or manual shutdown. Available program groups: up to 110 PATTEN. Usable memory capacity: 5000 SEGMENTS in total. Repeatable commands: each command can be up to 999 times. The production of the program adopts a conversational style, with functions such as editing, clearing, and inserting. SEGMENTS time setting 0~999Hour59Min. Programmable sequence control module device. With power-off program memory, it will automatically start and continue to execute the program after power is restored. Graphical curves can be displayed in real time during program execution. It has the function of automatically adjusting the freezing capacity. With scheduled start and shutdown functions. Button and screen lock (LOCK) function. |

|

8 Safety device |

|

|

8.1 Refrigeration System Protection |

●Compressor overheating ●Compressor overcurrent ●Compressor oil pressure overpressure protection ●Condensing fan overheated |

|

8.2 Chamber protection |

●Adjustable over-temperature protector ●Air conditioning channel limit over temperature ●Fan motor overheating |

|

8.3 Other protection |

●Leakage Protection ●Heating and humidification dry burning protection ●Overload and short circuit protection ●Over-temperature power-off protection ●Water tank protection |

|

9 Appendix |

|

|

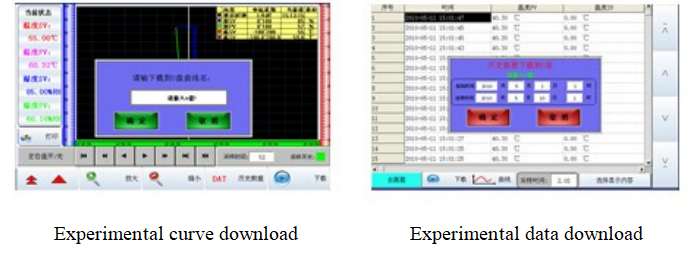

9.1 USB Interface (standard configuration) |

The controller can download historical curves and historical data. The historical data is saved in Excel format, and the required data can be downloaded by date. The historical data is saved in the form ofJPG pictures, which can be enlarged or reduced according to the needs, and then downloaded. |

|

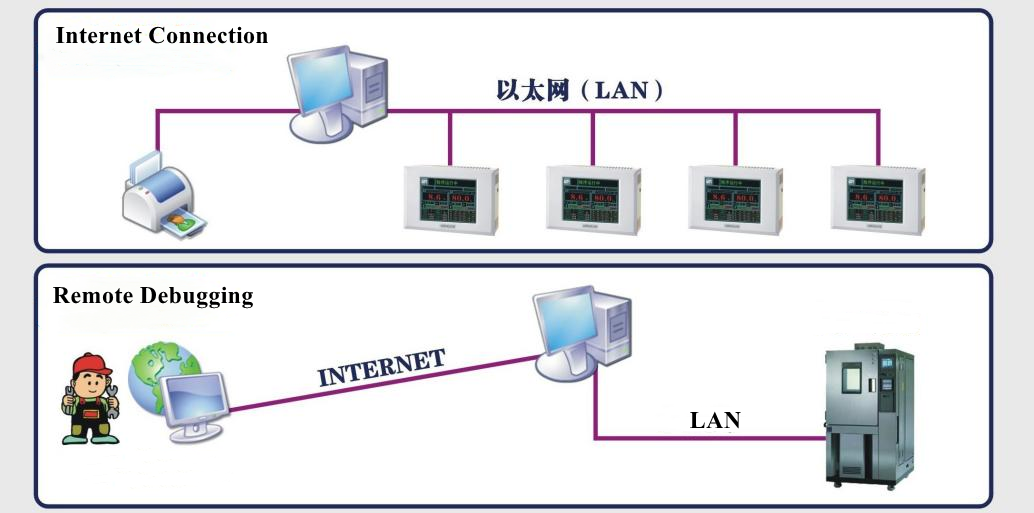

9.2 Remote control system and mobile APP control (requires optional function) |

|

|

10Transportation |

The test box is integrated and transported as a whole; (short-distance self-delivery, long-distance logistics) |

|

10.1 Size 10.2 Weight |

Maximum shipping dimensions (without packaging): see selection table "Dimensions" Maximum transport weight (without packaging): see selection table "Weight" |

|

11 Conditions of Use |

The user guarantees the following conditions |

|

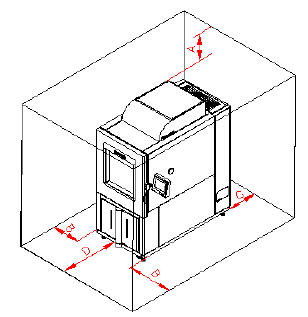

12.1 Installation site |

The ground is flat and well ventilated No strong vibration around the device There is no strong electromagnetic field around the device No flammable, explosive, corrosive substances and dust around the equipment

A:≥10cm B:≥60cm C:≥60cm D:≥150cm |

|

12.2 Environmental conditions |

Temperature: 5℃~30℃ Relative humidity: ≤85% Air pressure: 86kPa~106kPa |

|

12.3 Humidification water |

Bottled drinking water or distilled water, not unfiltered tap water; |

|

12.4 Power supply conditions power supply

|

AC220V single phase (must be connected to protective ground) Allowable voltage fluctuation range: ±10% V Frequency: 50Hz The grounding resistance of the protective ground wire is less than 4Ω The user is required to configure an air or power switch of corresponding capacity for the device at the installation site, and this switch must be used independently for this device (not for use with sockets) |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar