|

Profile |

|||

|

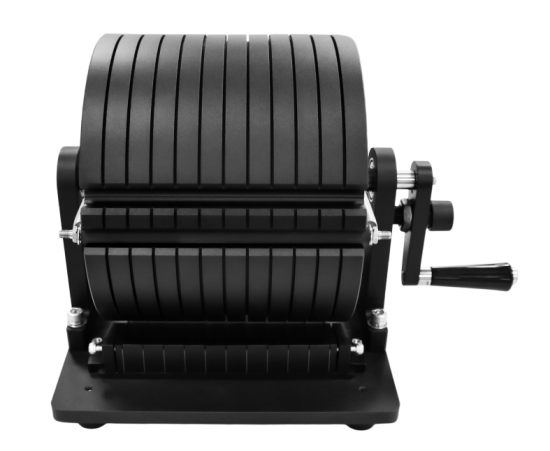

The UV Accelerated weathering test chamber stimulates dew and rain with consideration for humidity and/or water spray equipped with a fluorescent UV lamp which can completely simulate the UV spectra of sunlight, exposes materials to alternating cycles of UV light and moisture at controlled, elevated temperatures. It’s most widely used weathering tester to test types of damages include color change, gloss loss, chalking, cracking, crazing, hazing, blistering, strength loss and oxidation. The source adopts 8 pieces of UV lamps of 40W as the light source. The lamps are distributed on the two sides of machine, 4 pieces for each side (UVA-340 and UVB-313 optional), 8 pieces in total . |

|||

|

1.Main technical parameters |

|||

|

Item |

UV Lamp aging test chamber |

||

|

Model |

GB-OUV-115 |

||

|

Interior size |

W1140 X H500 x D500mm |

||

|

Exterior size |

W1300 X H1560 x D600mm |

||

|

Weight |

120kgs |

||

|

Controller |

-LCD 7-inch touch screen controller, with programmable temp., humid., UV(sun), and time and Fix mode of 2 running modes. -USB interface -Operation button -Alarm indicator -Irradiation timer |

||

|

Temp. control mode |

PID self-adjustment SSR control |

||

|

Temp. range |

RT+10℃ ~ 70℃ (adjustable) |

||

|

Temp. deviation |

±3.0℃ |

||

|

Temp. fluctuation |

±0.5℃ |

||

|

Humidity range |

≥93%R.H |

||

|

Temp. uniformity |

±1℃ |

||

|

Temp. fluctuation |

±0.5℃ |

||

|

Distance between lamps |

70 mm |

||

|

Distance between samples and lamps |

100 ± 10mm |

||

|

Irradiation level |

≤1.1W/m2 adjustable |

||

|

Adjustment |

Test period for Temp., irradiation, condensation, spray can be adjustable |

||

|

Irradiation lamp |

ATLAS Lamp UVA-340, L=1200/40W, 8pcs (average service life: 1600hrs)

|

||

|

Temp. control method |

PID self-adjustable SSR control |

||

|

Depth of water channel |

25mm under auto-control |

||

|

UV Wavelength |

UVA-340: 315 ~ 400nm; |

||

|

Test time |

0~999 H 99 min (adjustable) |

||

|

Function |

Temperature, light, condensation, spray test cycle is adjustable |

||

|

Black board Temp. |

50℃ ~ 70℃ (temperature inside the chamber plus 20℃ ~ 25℃) |

||

|

2.Structure & Material |

|||

|

a)Structure: The middle of the machine is the working chamber, the water system located at the bottom of machine, its top is the control cabinet and control panel. Open the door from front direction. The bottom of the chamber with high-quality PU activity wheel that can be fixed, users can move it according to their requirements positioning. -Single cycling system for air flue in the box, there’s one inlet axis weeding machine which improves the flow amount of air, the heating ability and the whole temperature uniformity in the test machine. -Water source and consumption: Tap water or distilled water for 8liters per day. -Heating method is to heat liner water tank with fast heating speed and high temperature uniformity. b)Material: -Inner box: high grade stainless steel plate -Outer box: stainless steel plate SUS304 or stoving varnish for option. |

|||

|

3.Spray System |

|||

|

-Using the manual control function of the controller, to observe the spray condition in the open-door state, so as to adjust or replace the nozzle. -The machine is equipped with a sprinkler, the sprinkler simulates the temperature upheaval and rain erosion during the rain, with a total of several nozzles, sprayed evenly. The spray time is set by the customer. -Inner water level is with automatic water replenishing. |

|||

|

4.Light source system |

|||

|

Types of light source (simulate the sunlight) Light source: 4 imported UV fluorescent lamps (ATLAS) with rated power of 40W, UVA-340 and UVB-313 light source for users to choose. Like other lamps, the aging of the QUV tube causes the lamp output to drop, and the QUV without the Irradiance meter control system uses the rotational position method to compensate. This system can be used for many application standards, but it has inherent limitations. This method of changing position does not compensate for the effects of different batches of lamps or the surrounding environment.

|

|||

|

5.UV Cycle Temperature control |

|||

|

The components of the UV cycle system include a blower, air heater, air distribution system, and blackboard temperature sensor. a)Blower: Installed in the lower tank air duct of the equipment, the blower is continuously operated throughout the UV cycle. b)Air heater: Installed in the air duct above the blower to heat the air blown by the blower when needed. c)Air distribution system: The air blown by the blower enters the test chamber through the air duct, and then the air guide to the entire chamber. |

|||

|

6.Heating system |

|||

|

a)High speed heating tube of U-shape titanium alloy; b)independent temperature control system and lighting system; c)temp. control and output power controlled by micro computer with high accuracy and high efficiency. d)Thermal protection function of heating system. -The black panel adopts the colorful touch screen controller or digital key pressing controller to control the heating process. PID self-regulation, monitoring all adopt the standard PT100 temp. sensor of black panel. Temp. of water tank adopts the colorful touch screen touch screen program to control the heating, water tank locates at the bottom of tank, there is electrical heating device. During the test process, there’s test phase is dark condensation which need to generate saturated steam of high temperature, when steam meet the cool temperature, it condenses into water on its surface. |

|||

|

7.USB port (standard) |

All the history curve and history data can be downloaded from controller as Excel or JPG according to date. |

||

|

8.Standards compliant |

|||

|

international testing standards: ASTM D4329, ISO 4892-3, ISO 11507, SAE J2020. |

|||

|

9.Safety protection device |

|||

|

a)Ground protection b)power source overload and short circuit breaker c)control loop overload and short circuit fuse protector d)water shortage protection e)thermal protection |

|||

|

10.Quality assurance system Sailham strictly follows the requirements of ISO9001:2015 quality management system and European CE product certification. |

|||

|

11.Standard accessories attached to machine |

|||

|

Stainless steel SUS # 304 Shelf layer 1pc Power cord 1pc A drain hole (8 mm in diameter) Operation and maintenance instructions 1 copy Controller manual 1 copy Warranty card 1 copy |

|||

|

12.Equipment ambient environment -Grounding resistance cable is less than 4Ω; -Requires users to configure the device at the installation site for the capacity of the air or power switch, and the switch must be independent for the device (plug-socket is not allowed); -Temperature: 5℃ ~ +30℃ -Humidity: ≤85% -Pressure: 86kPa ~ 106kPa -Power supply: AC220 (±10%) V, 50 / 60HZ -Power: 4.5KW |

|||

|

|

|||

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar