Industry Standard

ASTM F2338-2009(2013) Standard Test Method for Nondestructive Detection of Leaks in Packages by Vacuum Decay Method

YY-T 0681.18-2020 Sterile medical device packaging test method,

United States Pharmacopoeia USP1207 standard

Industry Application

Test Principle

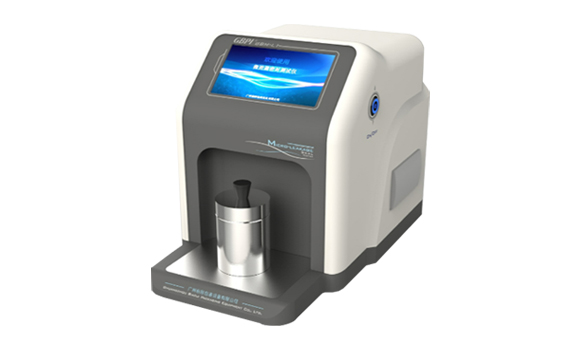

In accordance with ASTM F2338-2009 (2013), YY-T 0681.18-2020 and USP1207 standards, GBM-L1 is based on vacuum decay method with dual sensor technology and dual circulation system. The machine main body should be connected with specially-designed test cell contained with tested package.

The instrument evacuates the test cell, and a pressure difference is formed between the inside and outside of the package. Under pressure difference, the gas in the package diffuses into the test cell through the leak hole. The dual sensor technology detects the relationship between time and pressure and compares it with the standard value to determine whether the sample leaks.

Technical Specifications

| Item | Parameters |

| Absolute Pressure Test Range | (0~300) kPa |

| Differential Pressure Test Range | (-2~2) kPa |

| Detection Sensitivity | 1~2 μm |

| Balance/Test Time | 1~3600 s |

| Vacuum Purge Time | 1~3600 s |

| Set Flow Rate | 0~3 mL/min |

| Test System | Dual-sensor technology / Dual-loop testing |

| Test Chamber | Customized according to samples |

| Applicable Products | Vials, Ampoules, Prefilled syringes, Infusion bottles/bags, etc. |

| Detection Principle | Vacuum decay method |

| Main Unit Dimensions | 550 mm×330 mm×320 mm |

| Ambient Temperature | 20℃~25℃ |

| Relative Humidity | 40%~60% |

| Power Supply | AC 220V, 50HZ |

Product Features

1. Test cell customization available for different test samples to meet various requirements

2. Suitable for detecting micro leaks and also large leaks samples; the judgment of qualified or unqualified displayed

3. Use non-destructive testing method to carry out leak detection on the finished packaging, which causes no sample damage

4. 7-inch color touch screen, humanized operation is more convenient.

5. Use branded vacuum components, stable and durable.

6. Equipped with micro printer, USB data interface, PC software measurement and operation available, mbar and Pa interchangeable unit

7. Automatically saving of historical test records for local search

8. User classification authority setting to meet functions of GMP requirements, test record auditing and tracking

9. Automatically test results printing after test completion with manual operation to ensure accuracy and objectivity of the data.

We have engaged in developing environmentally friendly packaging test equipment. Compared with the traditional color water method, microbial challenge method of leak detection, vacuum decay method is a zero emission, high-efficiency, non-destructive physical testing method. It is the best for manufacturers, inspection institutions and scientific research institutes to detect the leakage of pharmaceutical and food packaging.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar