Apply for:

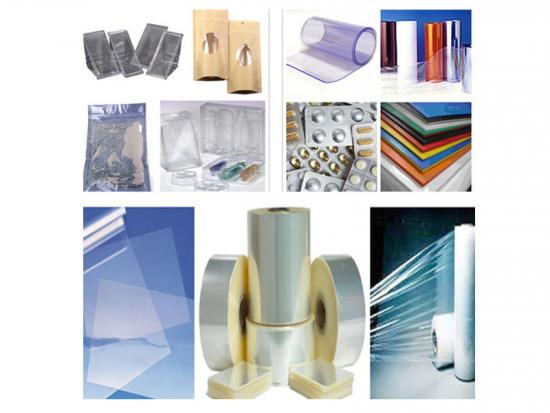

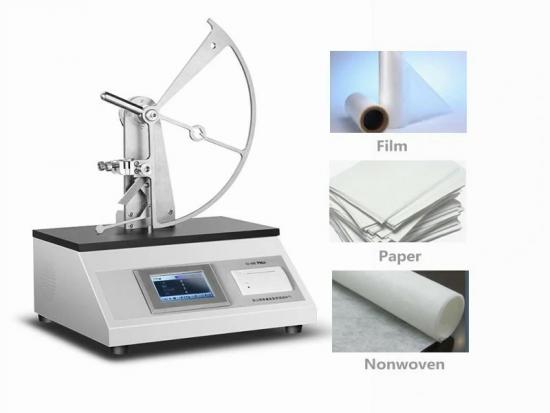

1) Plastic film, composite film, aluminum foil, aluminized film, etc.;

2) Plastic sheets, plates, rubber, ceramics, etc.;

3) Packaging containers, such as bottles, bags, bowls, etc.;

4) Expand applications, such as solar backplanes, liquid crystal display films, medical patches, etc.

Used in quality inspection, drug inspection, scientific research, packaging, film, food, pharmaceutical, daily chemical, electronics and other industries.

Features

Accurate and reliable data

Our company has approved and issued by the "General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China". Gas Permeability Tester "National Standard Material Classification Certificate" and "National Standard Material" Manufacturing Measuring Instruments License (GBW(E)130541/ 2). Use national standard materials to calibrate and verify the instrument to ensure the accuracy, versatility and authority of the test data.

Easy to operate

Professional software with simple interface, easy to use and flexibly to set test process.

Fully automatic operation, judge and stop automatically.

Five sets of curves of temperature, upper cavity pressure, lower cavity pressure, pressure difference change, and penetration are displayed in real time. The curves with conceal function, support query function for background data.

The OTR is equipped with a color touch screen, no external computer is needed.

Pneumatic clamps are used for sample placement, which is quick and convenient to operate.

Professional test report, automatically generate and can be exported in PDF format.

Advanced technology

Temperature control: Adopting the international advanced electromagnetic program stepping temperature control technology, automatic heating and cooling; high measurement accuracy, accurate to 0.1 ℃.

Support electronic signature function, online report submission and review.

High test efficiency

Each cavity can be tested independently, three identical or different samples can be tested, and three independent test reports can be produced to improve the effective test efficiency.

The measurement accuracy is up to 0.001 cm3/(m2·24h), and it can measure high-barrier materials such as aluminum foil.

Authority management and data tracking

The software is designed according to the requirements of the computerized system in the new GMP appendix.

The user name and password are required to log in to the workstation to ensure that the account and experimental data are safe and effective.

Users are divided into system administrator, instrument administrator, auditor and operator.

The system administrator can adjust the permissions of various levels; Such as adding and reducing system control items at a certain level.

It has audit tracking function (test tracking and log tracking), and each data change is recorded; Ensure the safety and integrity of test data.

Stable, reliable and easy to maintain

Imported oxygen sensor with high accuracy and good stability.

The sensor has an over-range automatic protection function to avoid damage to important sensors when the instrument fails

Functional modular design, easy to maintain.

Standard

ASTM D3985、ASTM F2622、ASTM F1927、ASTM F1037、ISO 15105-2、JIS K-7126-B、DIN 53380-3。

Technical Specification

| Item | Technical Parameters |

| Test Range | 0.01~1000 cm³/(m²·24h·0.1MPa) |

| Repeatability | 0.01 or 2%, whichever is larger |

| Resolution | 0.0001 cm³/(m²·24h·0.1MPa) |

| Temperature Control Range | 15~45°C |

| Temperature Control Accuracy | ±0.1°C |

| Humidity Control Range | 0%RH, 5~90%RH, 100%RH |

| Humidity Control Accuracy | ±2%RH |

| Permeation Area | 50.24 cm² (customized adapter available, minimum to 0.785 cm²) |

| Sample Size | Φ100 mm |

| Sample Thickness | ≤3 mm |

| Test Quantity | 3 pieces |

| Carrier Gas Pressure | ≥0.1 MPa |

| Carrier Gas Flow Rate | 5~100 mL/min |

| Pneumatic Pressure | ≥0.3 MPa |

| Overall Dimension | 700 mm × 655 mm × 390 mm |

| Weight | 60 kg |

| Power | 750 W |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar