Standards

ISO 2759, JIS P8112, ASTM D2210, TAPPI T403, QB/T 1057-2004, GB/T 454-2002, GB/T 1539, and GB 6545.

Specifications

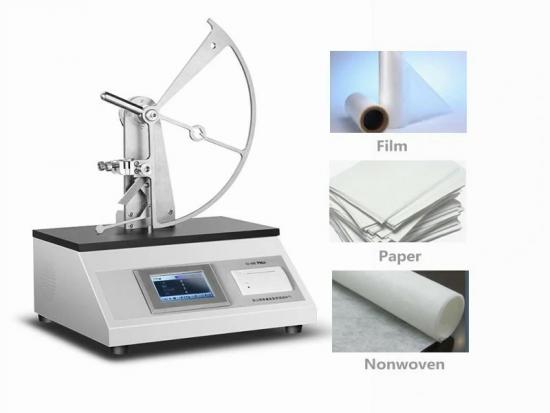

| Item | Parameter |

| Model | GNP-1 Type |

| Measurement Range | 40~1600 kPa (Range can be customized) |

| Resolution | 0.1 kPa |

| Indicated Accuracy | - Indication Error: ±0.5%FS |

| - Indication Variability: ≤0.5% | |

| Pressure (Oil Feeding) Speed | (95±5) ml/min |

| Diaphragm Resistance | - Bulge Height: 9 mm |

| - Diaphragm Resistance Value: (30±5) kPa | |

| Specimen Clamping Force | (0–2000) kPa (Adjustable) |

| Test System Sealing Performance | Pressure Drop < 10% pmax within 1 min |

| Instrument Dimensions (mm) | Approximately 500 × 750 × 505 |

| Overall Mass | Approximately 47 kg |

| Pressure Gauge Setting Pressure | (0.2~0.22) MPa |

| Air Compressor | - Air Displacement: (0.02~0.4) m³/min |

| - Rated Pressure: (0.6~0.8) MPa |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar