Every bite of peace of mind for babies starts with the ultimate safety of products. In the production and quality inspection of baby bottles, mechanical performance testing is a key link in safeguarding safety. Relying on a 0.5-class high-precision sensor (force measurement accuracy ±0.5% FS), a 1-500mm/min stepless speed regulation system, and an intelligent data analysis platform, Guangzhou Biaoji GBH-2 Electronic Tensile Testing Machine perfectly complies with GB 38995-2020 Safety Standard for Baby Bottles. From laboratories to production lines, it strictly checks the quality of baby bottles at every level!

Every bite of peace of mind for babies starts with the ultimate safety of products. In the production and quality inspection of baby bottles, mechanical performance testing is a key link in safeguarding safety. Relying on a 0.5-class high-precision sensor (force measurement accuracy ±0.5% FS), a 1-500mm/min stepless speed regulation system, and an intelligent data analysis platform, Guangzhou Biaoji GBH-2 Electronic Tensile Testing Machine perfectly complies with GB 38995-2020 Safety Standard for Baby Bottles. From laboratories to production lines, it strictly checks the quality of baby bottles at every level!

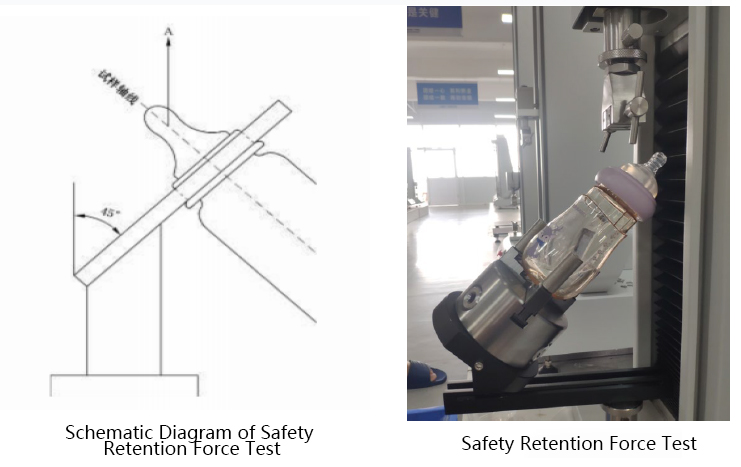

01 Mechanical Performance Test: Safety Retention Force Test

Test Scenario:

Simulate the connection strength of components when babies grip or shake the bottle, and the safety during use.

Conducted in Accordance with GB 38995—2020 Standard:

Mechanical testing equipment fixes the baby bottle with special fixtures, simulates the tension and force-bearing conditions of components in daily use (such as external force at a 45° angle to the bottle axis), detects the safety retention performance of components like nipples/drinking parts connected to the bottle body, and verifies whether components break or fall off during the test to ensure product safety in use.

Precise Positioning: Complies with standard requirements, stably clamps the bottle components at a position (10±2) mm from the top to ensure uniform test positions.

Non-destructive Clamping: The structures in contact with the bottle (such as gaskets and clamping surfaces) are designed to be gentle, avoiding damage to vulnerable components like nipples and bottle bodies, and preventing test failure caused by clamping damage.

Stable Force Transmission: The metal main structure has high strength, which can firmly fix the bottle during testing (when applying tension and thrust), without slipping or deformation, ensuring that the direction of external force application is consistent with the standard and the mechanical transmission is stable.

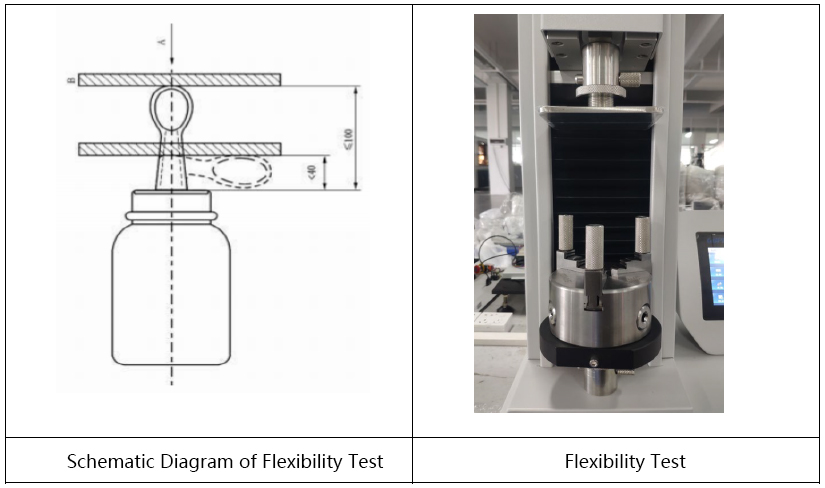

02 Mechanical Performance Test: Flexibility Test

Test Scenario:

The electronic tensile testing machine is equipped with a 100mm×100mm polished steel plate. The baby bottle sample assembled according to the product instructions is fixed by a fixture to ensure that the main axis of the bottle is perpendicular to the steel plate. Initially, the nipple/drinking part is allowed to deviate from the main axis by a maximum of 5°; the equipment applies a force of (10±1) N to the end of the part at a speed of (10±2) mm/min, and finally measures the distance from "the locking ring (if there is no locking ring, measure the bottle mouth of the bottle body) to the bending point of the part" to verify whether it is ≤40mm and detect the flexibility compliance of the part.

Precise Positioning: Adapts to the bottle structure, stably fixes the sample, ensures the main axis of the bottle is perpendicular to the polished steel plate, the initial deviation of the nipple/drinking part from the main axis is ≤5°, and the clamping position corresponds to the "locking ring (or bottle mouth of the bottle body)" reference to ensure test consistency.

Stable Force Transmission: It has a high-rigidity structure. When bearing a test force of (10±1) N and a loading speed of (10±2) mm/min, there is no slipping or deformation, and the force application direction perpendicular to the main axis is accurately transmitted to ensure the validity of test data.

Flexible Adaptation: Compatible with baby bottle types "with/without locking rings", the measurement starting point (locking ring or bottle mouth of the bottle body) can be adjusted to adapt to different bottle designs and realize "one-for-many" test adaptation.

Non-destructive Clamping: The parts in contact with the bottle (such as clamping surfaces and gaskets) are designed to be gentle, avoiding damage to vulnerable components like nipples and bottle bodies, and preventing the impact of clamping damage on test results.

03 Mechanical Performance Test: Compression Deformation Test

Test Scenario:

Simulate scenarios such as transportation extrusion and babies stepping on by mistake. Select the middle part of the bottle and the position of the maximum outer diameter (for special-shaped bottles, additional tests on the vertical direction of the maximum outer diameter are required, avoiding edges/corners and reinforcing ribs) as test points; apply a vertical force of 20N to the test points through a press tool, measure the outer diameter before and after pressurization, and calculate the diameter change rate using a formula (take the maximum value of a single bottle and the average value of three bottles); during judgment, products without a compressible statement must meet the requirement that the change rate is ≤10%, so as to simulate daily pressure-bearing scenarios and verify the compliance of the bottle body's compression deformation.

Precise Positioning: Adapts to the test points of the middle part of the bottle and the maximum outer diameter (the vertical direction can be expanded for special-shaped bottles), and can avoid edges/corners and reinforcing ribs to ensure that the test position is consistent with the standard and the data comparability is guaranteed.

Stable Force Transmission: Adopts a rigid structure + vertical loading design, with no deviation or deformation when applying a force of 20N, ensuring that the pressure acts evenly on the test points, accurately transmitting the load, and avoiding the impact of uneven force on the calculation of the diameter change rate.

Diverse Adaptation: Compatible with round and special-shaped baby bottles, the clamping/press tool structure can be flexibly adjusted, and it is suitable for designs "with/without locking rings" (the measurement reference is switched to the bottle mouth of the bottle body), covering different product forms.

Non-destructive Protection: The press tools and clamping surfaces in contact with the bottle are designed to be gentle/adapted to curved surfaces, avoiding damage to the bottle body (such as scratches and extrusion deformation), ensuring the integrity of the bottle body before and after the test, and not interfering with the result judgment.

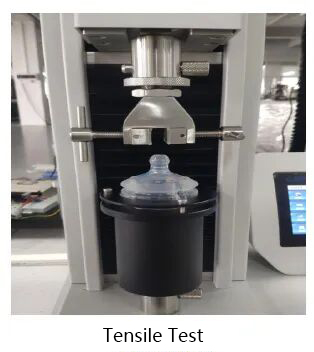

04 Mechanical Performance Test: Nipple Tensile Test

Test Scenario:

Simulate the continuous pulling force and sudden tearing when babies suck.

Test Process:

The electronic tensile testing machine uses special fixtures to non-destructively clamp both ends of the baby bottle sample along the axis direction (such as the connection between the nipple and the bottle body, component interfaces, etc.); first apply a pre-tension of (5±2) N to check the clamping state of the sample, then increase the load to (90±5) N at a rate of (200±10) mm/min and maintain it for (10±0.5) s; monitor the fixtures throughout the process to ensure non-destructive clamping (if the clamped part is damaged, the test is invalid), and observe whether the baby bottle sample breaks or falls off under tension to verify whether the tensile performance meets the standard requirements.

Precise Axis Alignment: Through the design of symmetric clamping surfaces and centering pins/grooves, the two ends of the sample are forced to be clamped coaxially along the axis, ensuring that the tension direction is consistent with the axis and avoiding test failure caused by eccentric load.

Non-destructive Clamping Protection: The clamping surfaces adopt a flexible adaptive structure (such as rubber gaskets, curved fitting design) or precise pressure control to avoid damage to vulnerable parts such as nipples/interfaces and prevent the test results from being invalid due to clamping damage.

Convenient and Flexible Sample Installation: Supports quick clamping (such as knob/pneumatic clamping), adapts to the sizes of different baby bottle components (nipples, components), and facilitates non-destructive sample installation along the axis direction, improving test efficiency.

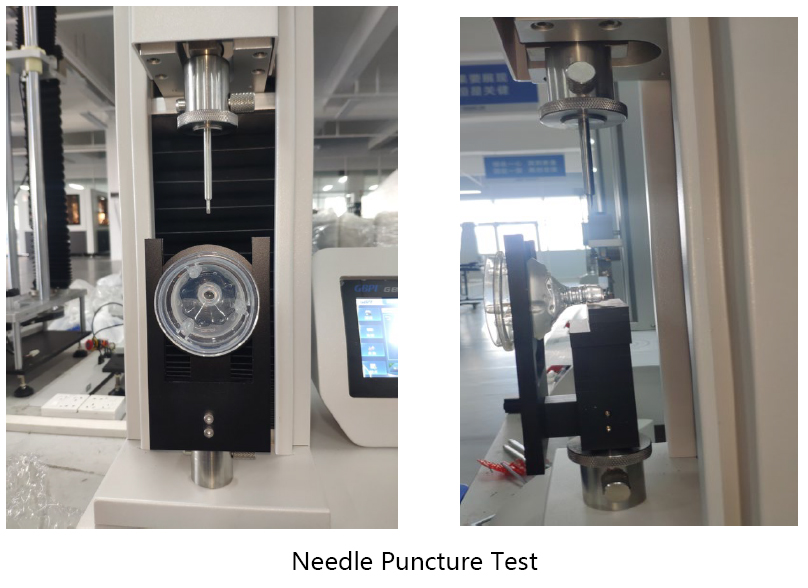

05 Mechanical Performance Test: Needle Puncture Test

Test Scenario:

Simulate accidental contact with sharp objects (such as key scratches, falling collisions).

Test Process:

Place the baby bottle sample on a panel with a thickness of ≥10mm and a Shore D hardness of (70±5). A sharp needle (made of materials such as H13 high-chromium tool steel, with a hardness of HRC 45-50) is directed at the waist/neck area of the bottle body (15-20mm from the top; if the sample has no circular cross-section, select a flat part of the neck) along the vertical direction of the sample axis; the testing equipment drives the sharp needle to puncture at a rate of (10±5) mm/min, applies a force of (200±10) N and maintains it for (1±0.5) s, and visually observes the state of the sample during the process; before the test, it is necessary to check that the sharp needle is undamaged, so as to simulate the possible puncture risk of sharp objects in daily life and verify the needle puncture resistance of the baby bottle.

06 GBPI Tensile Testing Machine Series

GBPI GBH-2 Electronic Tensile Testing Machine is developed based on standards such as GB, JIS, and ASTM, and can adapt to the testing scenarios of various baby bottle components through customized fixtures. Relying on high-precision sensors (force measurement accuracy ±0.5% FS), ball screw loading, and flexible parameter settings, it can accurately conduct mechanical performance tests on baby bottles, such as tensile testing (step-by-step loading along the axis to verify component connection strength), needle puncture testing (simulating sharp object puncture according to standard speed and force value), and compression deformation testing (applying force to the bottle body to measure the diameter change rate); it collects force-deformation data in real time, generates curves, and ensures test safety with limit and overload protection. It provides a reliable basis for judging whether the performance of baby bottles, such as tensile fracture resistance, damage resistance, and deformation resistance, complies with GB 38995—2020 standard, and is a core equipment for verifying the mechanical performance quality of baby bottles.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar