Material packaging is an integral part of any pharmaceutical industry. Packaging affects the quality stability and labeling of pharmaceutical products. Packaging provides a sufficient degree of protection to minimize the loss of ingredients and should not physically or chemically interact with the contents in a way that would alter their quality beyond the limits specified in individual monographs or present a risk of toxicity. Common packaging methods include containers that can be made of glass, plastic, metal or paper. Each type of packaging needs to be tested to determine the quality of the packaging material, and the testing of packaging materials is required depending on the packaging container and the type of drug material, and the testing methods will vary. For example, commonly used tests are water vapor transmission rate test , leak test , thermal adhesion performance test, etc.

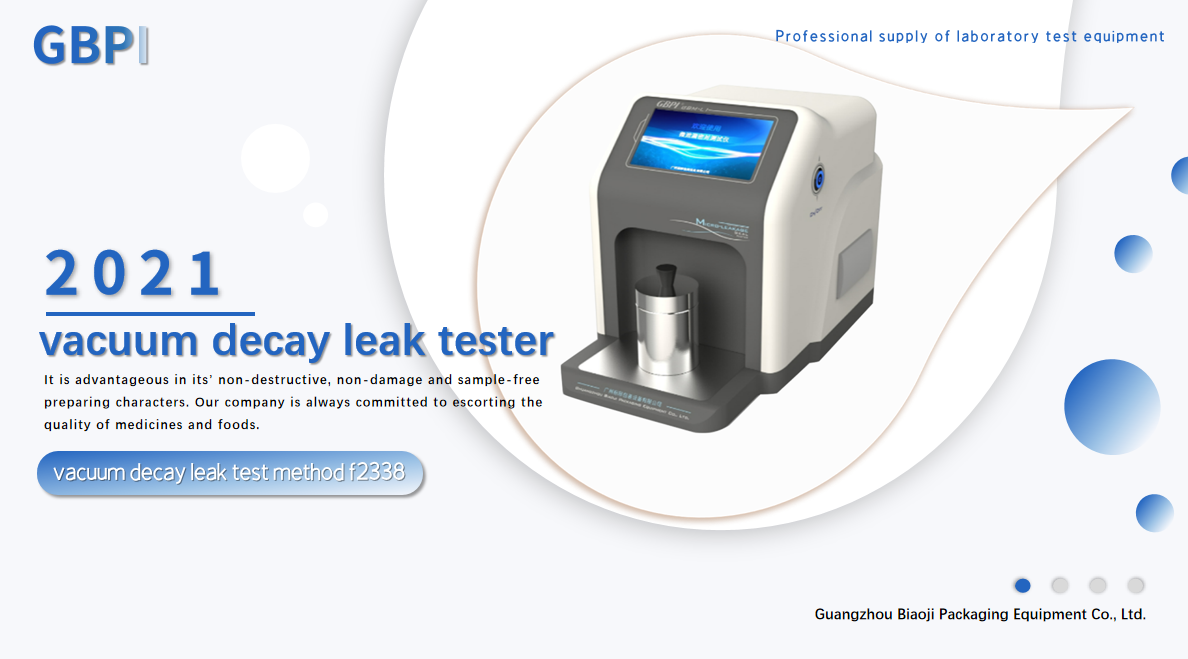

The GBM-L1 Vacuum Decay Leak Detection Tester developed by GBPI can meet the testing requirements.

GBM-L1 Vacuum Decay Leak Detection Tester is used to perform micro leakage detection on finished packaging by vacuum decay method in accordance with ASTM F2338-09. It is suitable for leak detection for the integrity of various packaging containers and applied to ampoules, vials, HDPE bottles, prefilled needles and It is advantageous in its' non-destructive, non-damaging and sample-free preparing characters. Our company is always committed to escorting the quality of medicines and foods.

The host is connected to a vacuum attenuation chamber, the sample is put into this chamber and vacuumed, there is a pressure difference inside and outside the sample, the gas enters the vacuum attenuation chamber and the host through the leakage hole, the host uses the pressure sensor and the differential pressure sensor to monitor the change of vacuum in the test chamber, and judge whether the sample is qualified by the amount of vacuum change.

Micro-leakage sealing instrument adopts the principle of vacuum and differential pressure dual sensor method, can detect pressure and time changes, with vacuum, test and infiltration time can be adjusted, test data can be all not stored in the database, to ensure that you can observe and analyze the test data in detail, by the majority of drug manufacturers like.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar