Types of pet food packaging

For pet food manufacturers, choosing the right packaging material is very important to ensure the shelf life of the product. Therefore

strict quality control of packaging materials and packaging is required.

The main types of pet food packaging on the market include two main categories: metal cans for packaging wet food and dry pet

Multi-layer food bags.

Pet food packaging is available in a variety of forms for different sizes of pet food packaging. Common packaging samples currently on the market formulations mainly include: aluminum steel cans, aluminum foil trays, laminated film flexible packaging, paper bags, cardboard boxes, multi-layer fiber composite containers, the disposable convenience packaging and other forms of packaging. The materials used for pet food flexible packaging are: pet, Al, PE, OPP ,CPP, CPPP, VMPET, BOPA, rcpp, etc.

It is known that microorganisms multiply in the environment of temperature, oxygen and water. Oxygen is the main external cause of rancidity. The lower the oxygen content, the less the possibility of rancidity, while water may be the microorganism. Therefore, it is important to test the integrity and barrier properties of pet food bags.

Barrier properties of packaging materials

During the shelf life, oxygen and moisture in intact pet food packaging come mainly from oxygen and water vapor that seep through the packaging.

Barrier refers to the barrier effect of the packaging material on the passage of gas or liquid molecules through the material. GBPI's water vapor transmission rate tester can test oxygen permeability for BOPET/VMPET/LDPE and aluminum and plastic laminate films separately. analysis and comparison. The greater the oxygen permeability, the worse the material's resistance to oxygen; the greater the water vapor transmission rate. Oxygen transmission rate parameters inside the package can also be tested using the GBPI Y110 2.0 oxygen transmission rate tester system

Package Integrity

By checking the integrity of the packaging, the quality control of pet food packaging can be effectively carried out to avoid the pet food packaging in the production, transportation or storage process of packaging breakage, to ensure the shelf life and product quality of pet food.

1. Pet food packaging overall sealing test

Sealing performance test can determine the overall integrity of pet food packaging, which can be divided into positive pressure test and negative pressure test.

2 pet food packaging bag peel strength and heat seal strength test

Through the GBPI series of intelligent electronic tensile testing machine to test the peel strength of the packaging bag, you can visually determine the composite packaging bags of composite quality.

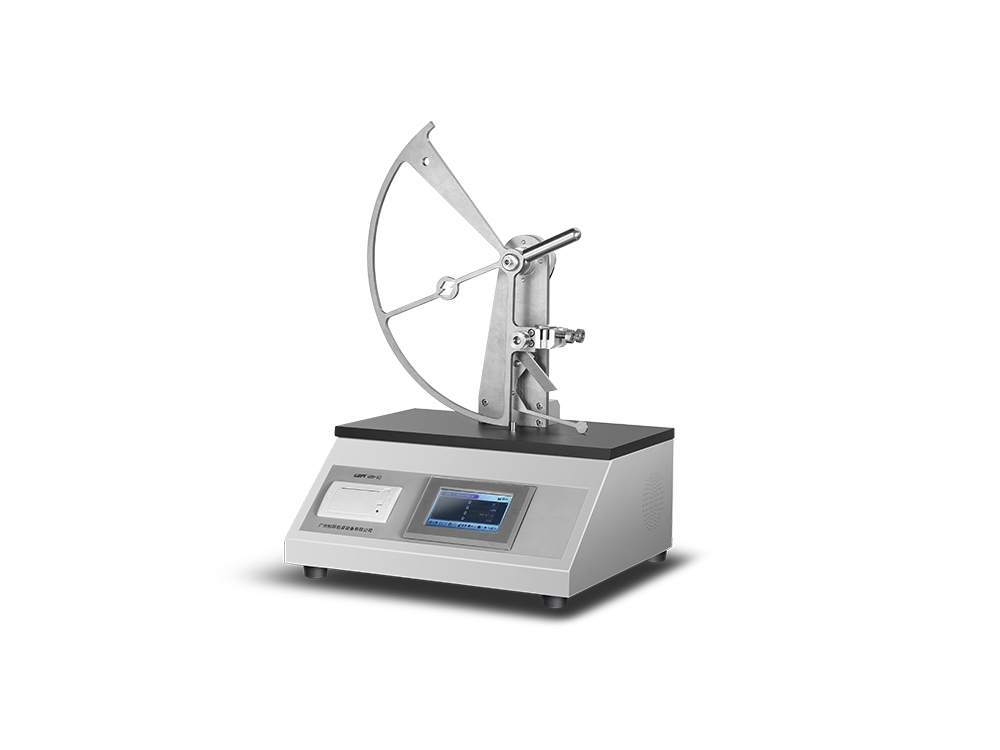

3, pet food packaging bag tearing degree

GBD-S tear tester uses elemendorf method. Test principle and method is to lift the pendulum to a certain height, so that it has

certain potential energy, clamp the specimen, cut a gap in the direction of its tear, when the pendulum falls, the use of its own stored potential energy will specimen tearing. sample, calculate the energy consumed to tear the sample, so as to obtain the force required to tear the sample and judge the packaging resistance to tearing.

In summary, the integrity of the packaging will directly affect the safety of pet food. Therefore, in order to ensure the quality of pet food and extend the shelf life of pet food, it is important to test the integrity of the packaging.

Therefore, in order to ensure the quality and extend the shelf life of pet food, it is necessary to test the integrity of the packaging. Through the inspection of packaging integrity, the pet food manufacturers can monitor the quality of packaging and timely adjust the packaging materials or packaging according to the test results the packaging process can also avoid the quality of pet food problems due to the quality of packaging.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar