Abstract: Plastic ampoules are widely used in the pharmaceutical industry due to their convenience, ease of opening and safety. However, compared with glass ampoules, the oxygen barrier performance of plastic ampoules is lower, which may lead to the deterioration of samples. Therefore, the oxygen barrier performance of plastic ampoules is one of the key performance indicators for pharmaceutical manufacturers to consider. In this paper, the oxygen permeation rate of plastic ampoules was tested by using Y310 Coulomb Electricity Method Oxygen Permeation Tester developed by GBPI. The test standard, test procedure and test results were introduced, and the oxygen barrier performance of plastic ampoules was effectively evaluated by taking the whole plastic ampoule as the test object.

Ampoules

Ampoule is a kind of sealed vial used for storing injection, vaccine, serum, etc. The capacity is usually 1~25 mL, and it can also be used for storing oral solution. Glass ampoules were firstly used, but there have been many problems such as not easy to open with bare hands, risk of cutting fingers, easy to wear the drug markings on the surface of the bottle, and the glass fragments from opening may cause infusion reactions, which affect the safety of medication use. Due to its advantages, plastic is gradually becoming a substitute for glass ampoules. Compared with traditional glass ampoaules, plastic ampoules are convenient to operate, easy to open, less likely to produce fragments and particles during opening, and have high safety, and are widely used in many pharmaceutical industries.

In the process of application, the oxygen barrier performance of plastic ampoule is one of the main factors affecting the quality and safety of drugs. If the oxygen barrier performance of plastic ampoule is low, i.e. the oxygen transmission is high, some components of the drug will easily react with the oxygen penetrating into the container and be oxidized, resulting in discoloration, precipitation, reduced efficacy and even toxic substances. Therefore, drug manufacturers should pay attention to the oxygen barrier performance of plastic ampoules and strengthen the monitoring of oxygen transmission rate of plastic ampoules.

Testing standards

There is no pharmaceutical industry standard for oxygen transmission rate testing of plastic ampoules. Due to the unique opening structure and molding process, the thickness of the plastic at the opening fracture is smaller than that of the other parts. The different thicknesses further cause the difference in oxygen transmission rate of different parts of the plastic ampoule, so the oxygen transmission rate of the plastic sheet cannot be used to indicate the overall barrier performance of the plastic ampoule. The oxygen barrier performance should be evaluated from the perspective of testing the whole container. The standard used for the test involved in this paper is GB/T 31354-2014 "Test Method for Oxygen Permeability of Packaging Parts and Containers Coulometer Test Method", which was officially implemented in March 2015 and stipulates the test method for testing the oxygen permeability of packaging parts and containers by coulometer method under steady-state conditions.

Testing Instruments

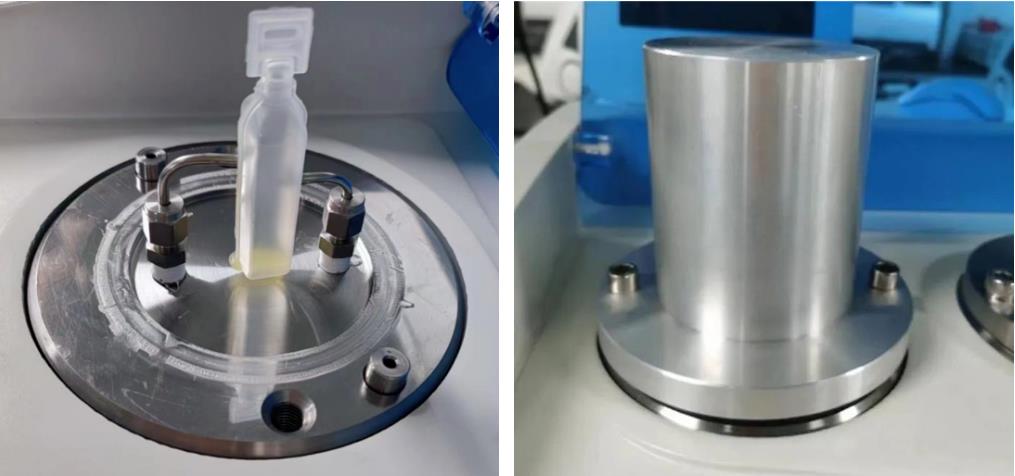

The GBPI self-developed Y310 Coulomb Oxygen Transmission Rate Tester is equipped with a special fixture for testing plastic ampoules, and the Y310 Coulomb Oxygen Transmission Rate Tester is based on the testing principle of Coulomb Oxygen Sensor. At the same time, the intelligent operating system is designed according to GMP Appendix "Computerized System", with multi-level authority management and audit trail function, which can meet the demand of data traceability in pharmaceutical industry. This testing equipment conforms to domestic and international standards such as GB/T 31354, GB/T 19789, YBB 00082003, ASTM D3985, ASTM F2622, ASTM F1927, ASTMF1307, ISO 15105-2, DIN 53380-3, JIS K-7126-B, etc.

Test samples

Four types of plastic ampoules from a customer. The numbers are 1~4.

Sample condition adjustment and test environment

According to GB/T 31354-2014, the laboratory environmental conditions were 23±2℃ for temperature and 50±10% for relative humidity.

Under the test conditions, the specimen state adjustment was carried out for more than 48h.

Testing process

1. Place the plastic ampoule to be tested on the special test fixture and seal the hole between the middle of the plastic tube and the fixture with sealing grease. After the sealing is completed, cover the fixture with the outer cover and tighten it.

2. Turn on the power of the instrument, connect the air source and adjust the pressure of the air source to a suitable size.

3、Set the name of the sample to be tested, test temperature, humidity and other parameters in the setting interface.

4、Start the test.

5、After the test, the instrument automatically calculates and displays the test results.

Test results and analysis

The oxygen transmission rates of the four plastic ampoules (1~4) tested were 0.0285 cm³/(pkg.24h), 0.0414 cm³/(pkg.24h), 0.0303 cm³/(pkg.24h) and 0.0464 cm³/(pkg.24h).

The result is the oxygen transmission rate of the container with the plastic ampoule as a whole as the test object, which is a comprehensive examination amount of the raw material and processing process of the plastic ampoule, and can help the pharmaceutical manufacturers, quality inspection departments and other units to effectively evaluate the oxygen barrier performance of the plastic ampoule to ensure the safety and effectiveness of the drugs during the shelf life. It is suitable for testing the oxygen transmission performance of films, sheets, papers, packaging parts and related materials in the fields of food, pharmaceuticals, medical devices, daily chemicals, photovoltaic electronics, etc. It provides a wide range and high efficiency of oxygen transmission rate testing for high, medium and low oxygen barrier materials. Oxygen transmission rate testing for high, medium and low oxygen barrier materials.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar