- Packaging lab equipment high accuracy barrier film water vapor permeability analyzer moisture vapour transmission rate

Application

W413 2.0 water vapor permeability tester is designed to test the water vapor transmission rate (WVTR) of films or sheets materials.

- Water vapor permeability tester

- moisture vapour transmission rate

- water moisture tester

- packaging lab equipment

- barrier film water vapor permeability analyzer

- water vapor transmission rate tester

Tags :

- W812 Water Vapor Permeability Analyzer(Cup Method) WVTR Testing Equipment For Packaging

Product introduction

This product is based on the test principle of cup method water vapor transmission, and is designed and manufactured according to ASTM E96, GB/T 1037 standards, and provides a wide range and high efficiency water vapor transmission rate detection for low, medium and high water vapor barrier materials. test.

It is suitable for the water vapor transmission performance test of films, sheets, paper, fabrics, non-woven fabrics and related materials in the fields of food, medicine, medical equipment, daily chemicals, etc.

- Water Vapor Permeability of Foils and Films

- moisture tester for food material packaing

- WVTR Testing Equipment For Packaging

- Permeability tests

- digital moisture tester

Tags :

- Moisture vapor transmission rate (MVTR)-AUTO W806View More

product description

This product is based on the principle of water vapor transmission test by cup method and designed and manufactured with reference to ASTM E96, standard, providing a wide range and high efficiency water vapor transmission rate test for low, medium and high water vapor barrier materials.

It is suitable for water vapor transmission performance testing of films, sheets, papers, fabrics, nonwovens and related materials in the fields of food, pharmaceuticals, medical devices, daily chemicals, etc. - Gravimetric Method Water Vapor Permeability Analyzer-AUTO W812View More

product description

This product is based on the test principle of cup method water vapor transmission, and is designed and manufactured according to ASTM E96, GB/T 1037 standards, and provides a wide range and high efficiency water vapor transmission rate detection for low, medium and high water vapor barrier materials. test.

- high accuracy barrier film Electrolytic sensor method water vapor permeability analyzer-W203 2.0View More

Introduction

Based on the test principle of electrolytic sensor method, W203 2.0 Water Vapor Permeability Analyzer is designed and manufactured according to GB/T 21529, ISO15106-3 standard, based on the test principle of electrolytic method.

W203 2.0 is suitable for the water vapor transmission performance test of films, sheets,

papers, packages and various materials in the fields of food, medicine, medical equipment,

daily chemicals, photovoltaic electronics, etc. It is an ideal configuration instrument for testing the barrier properties of packaging materials in the packaging production industry whether offline or online

- W416 2.0 Water Vapor Transmission Rate TesterView More

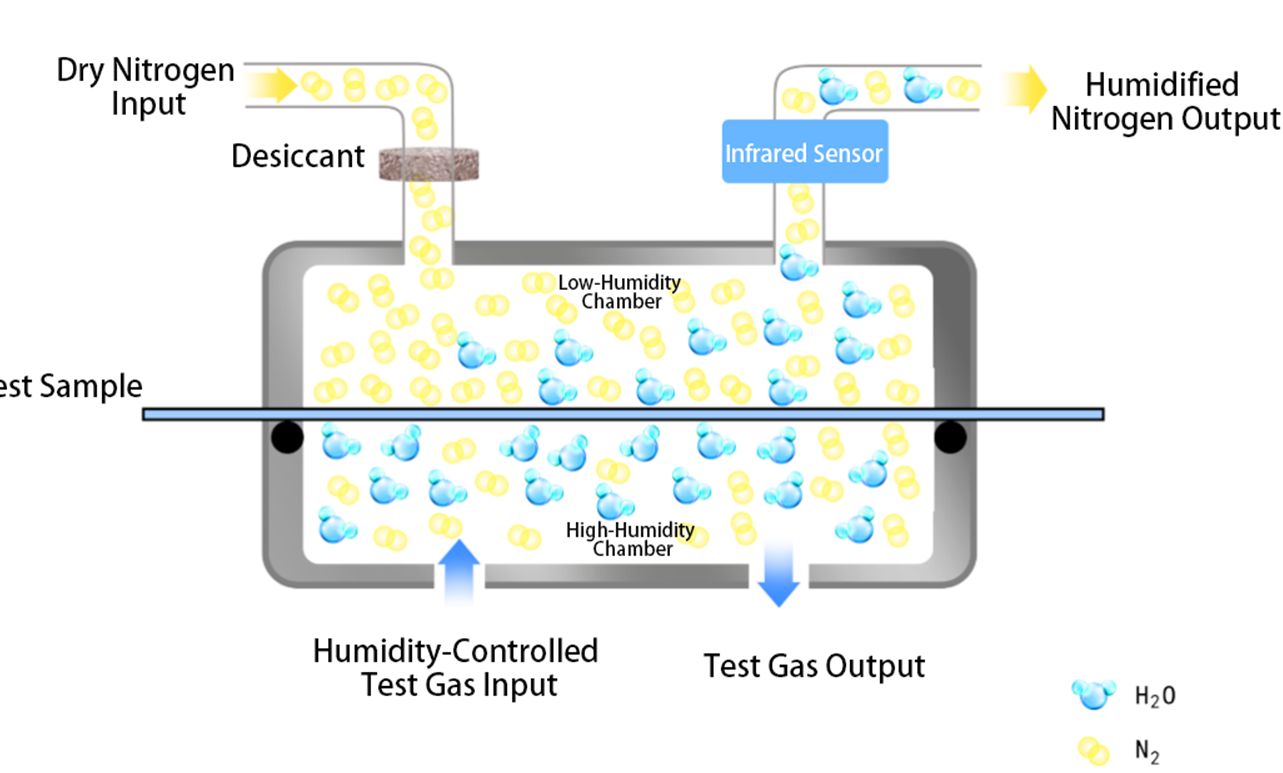

Product Profile • The W416 2.0 Infrared Method Water Vapor Transmission Rate Tester is a high-end precision testing instrument for packaging materials, newly developed and upgraded by Guangzhou Standard International R&D Team in full compliance with the requirements of **GB/T 26253** and **ASTM F1249** standards as well as market demands. • Based on the testing principle of infrared moisture analysis sensors, it provides wide-range, high-efficiency water vapor transmission rate (WVTR) testing for high, medium and low barrier materials. • It is suitable for testing the water vapor transmission performance of films, sheets, papers, packages and other related materials in industries such as food, pharmaceuticals, medical devices, daily chemicals, photovoltaic electronics, etc. • It is an ideal offline or online configuration instrument for manufacturers in the packaging industry to test the barrier performance of packaging materials. Testing Principle The W416 2.0 Water Vapor Transmission Rate Tester adopts the infrared method principle: 1. Fix the pre-treated sample in the middle of the test chamber, dividing the chamber into a high-humidity chamber and a low-humidity chamber. 2. Compressed air flows through the high-humidity chamber, while dry nitrogen (carrier gas) flows through the low-humidity chamber at a constant flow rate. 3. Due to the humidity gradient, water vapor penetrates from the high-humidity chamber to the low-humidity chamber. 4. The water vapor passing through the sample is carried to the infrared sensor by the flowing dry nitrogen. 5. Parameters such as the sample’s water vapor transmission rate are derived from the electrical signal output by the sensor.

Working Principle Diagram of Infrared Method

Standards • ISO 15106-2 • ISO 21760-1 • ASTM F1249 • GB/T 26253 • JIS K7129-2 • Chinese Pharmacopoeia 2025 Edition <4010 Determination of Water Vapor Transmission Rate of Pharmaceutical Packaging Materials> • YBB 00092003

Technical Parameters

Item Technical Parameter Test Range 0.002 ~ 100 g/(m²·24h) Repeatability The greater value between 0.005 or 2% Resolution 0.0001 g/(m²·24h) Temperature Control Range 15 ~ 45℃ Temperature Control Precision ±0.1℃ Humidity Control Range (5 ~ 90)%RH, 100%RH Humidity Control Precision ±1%RH Test Area 50.24 cm² Sample Size Φ100 mm Sample Thickness ≤ 3 mm Sample Quantity 6 pieces Carrier Gas 99.999% Nitrogen (provided by the user) Carrier Gas Pressure ≥ 0.1 MPa Carrier Gas Flow Rate 5 ~ 100 mL/min Pneumatic Pressure ≥ 0.3 MPa Dimension 1140mm × 600mm × 440mm Weight 55 kg Power 750 W Power Supply AC 220 V, 50 Hz

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar