In the production process of rubber, plastic and other products, in order to prolong the service life of the product and have good anti-oxidation, smoothness, flexibility and other properties, antioxidants, anti-blocking agents, plasticizers and other additives are often mixed. In addition to this, it is difficult to completely react the individual monomers used to prepare the product. Experiments have shown that these additives and residual monomers will slowly migrate outward in rubber, plastic and other products. When rubber and plastic products are in direct contact with food and medicine in packaging or other forms, these substances are likely to migrate. In food and medicine, food safety incidents such as "liquor plasticizer incident" and "toxic plastic wrap incident" are all related to the migration of harmful substances in packaging. Monitoring of Migratory Substances in Articles. Pacifiers are mostly used by infants and are in direct contact with the milk powder and oral cavity. The functional development of various organs of infants is not perfect. There are more migratory substances in the pacifier, which is more harmful to the baby. The total amount of control to ensure the safety of infant food intake. Each country has national standards, such as Thailand

Thailand mandates TIS 1025-2562 (2019) as a new standard for pacifiers. This will take effect on December 13, 2021.

On June 16, 2021, the Ministry of Industry of Thailand published a regulation in the Government Gazette requiring TIS 1025-2562 (2019) as a standard for pacifiers (the regulation). This industry standard is mainly based on EN 1400:2013+A1:2014 and contains requirements related to the materials, construction, performance, packaging and product information of such products. It is built with reference to information from the manufacturer, the user and the following documents:

EN 1400:2013+A1:2014 "Children's use and care articles - Pacifiers for infants and young children - Safety requirements and test methods"

EN 71-3:2013+A2:2017 'Safety of toys - Part 3 "Migration of certain elements"

EN 12868:2017 'Children's use and care articles - Method for determination of the release of N-nitrosamines and N-nitroso substances from elastomer or rubber teats and pacifiers

DIN 53160-1:2010 "Determination of colour fastness of commonly used articles - Part 1: Artificial saliva test"

ISO 105-A03:1993 'Textiles - Tests for colour fastness - Part A03: Grey scales for assessing dyeing'

Ministry of Health Circular (No. 369) BE 2558 (2015) Re: Bottles and Containers for Infants and Young Children.

TIS 1025-2562 (2019) also requires certain nipple materials/components to comply with certain chemicals/tests involving:

Migration of 17 elements

Release of N-nitrosamines and N-nitroso species

2-mercaptobenzothiazole release

Antioxidant release

formaldehyde release

Bisphenol A (BPA) release

Color fastness

Volatile compound content

Test methods and instruments

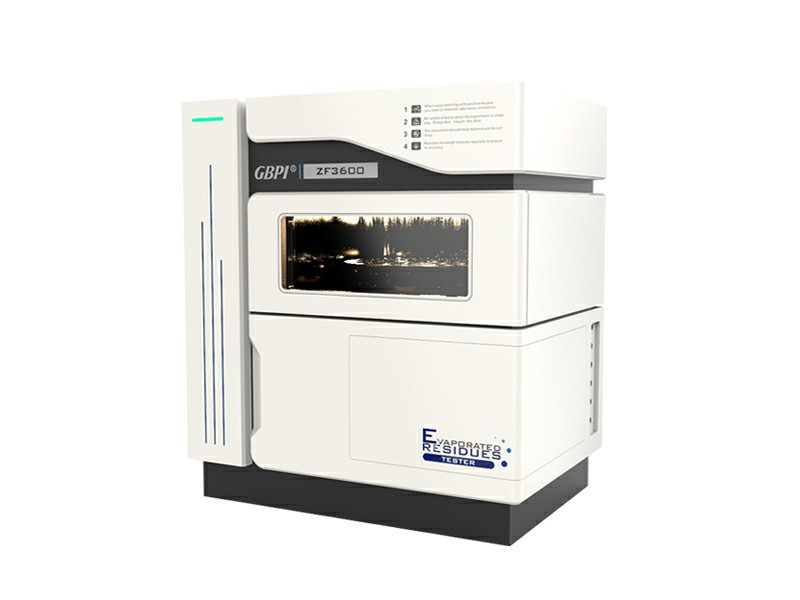

The AUTO ZF3600 total migration and non-volatile matter analyzer has an integrated system design of water bath evaporation, heating and drying, drying and cooling, and constant temperature weighing. The test process is fully automated without manual participation. It is suitable for testing the total migration (non-volatile matter, evaporation residue) and other items in the fields of purified water, pharmaceutical packaging materials, food packaging, cigarette tipping paper and chemical reagents. It can also be applied to the water content, loss on drying and other items of solid samples, and the total dissolved solid content test in water quality testing.

Test principle

Put the solution to be tested into the solvent storage dish of the automatic feeding system, and the empty cup is heated, cooled and weighed at the set temperature. Repeat the steps until a constant weight value is reached. Evaporate to dryness on a water bath below the boiling point of the soaking liquid. The cavity is heated to 105°C, dried and cooled. After the evaporating dish is cooled, the constant weight is judged with a balance (sensitivity is 0.01 mg), and the experiment is terminated to meet the constant weight requirement of the project.

Test samples and test procedures

Test sample: baby pacifier

Experimental procedure:

1. Migration process:

(1) Different soaking solutions are selected, and the total amount of substances migrated is different. The pacifier is in contact with water-based, non-acidic food with an ethanol content of less than 8%, so the soaking liquid selected in this test is distilled water.

(2) Add distilled water at 40°C to the sample to be tested, and place the sample to be tested containing distilled water in an environment of 40°C for 24 hours, and do a blank test at the same time.

2. Weighing process:

(1) Take the soaking solution and blank reagent and put them in an evaporating dish with constant weight and evaporate to dryness.

(2) Transfer the evaporating dish to the corresponding numbered tray rack in the evaporative residue constant weight meter, set parameters such as drying time and drying temperature, and click the test option to start the test.

(3) After the test, the device will automatically display the test results.

Test Results and Analysis

The total migration in the nipple samples tested in this test was 2.9 mg/kg.

The total migration of migratory substances in rubber and plastic products that are in direct contact with food and medicine is one of the important properties that affects the safety of their use. Strictly controlling and strengthening the monitoring of the total migration will improve product quality and prevent pollution. Food and medicine are of great significance. GBPI's Evaporation Residue Constant Weight Meter has the advantages of accurate testing, high intelligence and convenient use in detecting total migration. GBPI is a high-tech enterprise specializing in the research and development, production and packaging testing services of packaging testing equipment. The existing testing equipment includes gas transmission rate tester, oxygen transmission rate tester, water vapor transmission rate tester, intelligent Electronic tensile testing machine, friction coefficient tester, heat shrink tester, sealing tester, heat sealing tester, headspace gas analyzer and other testing instruments of packaging.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar