Test standards

• B-T3682-2018 Determination of melt flow rate and melt volume flow rate for thermoplastics

· ISO1133: 1997 Determination of melt mass flow rate MFR and melt volume flow rate MVR for thermoplastics

· ASTM D1238 Standard test method for determination of flow rate of thermoplastics melt by extruded plastimeters

Product advantages

1. The heating cylinder is made up of 304 stainless steel or alloy, for the reason that in high temperature metal material is easily oxidation rust while the melting flow index tester usually performs long-time work at high temperature(up to 400~500 degrees).

2. The melting flow index rate instrument is equipped with dual sensor configuration to get precise temperature control and better temperature gradient so that the instrument can work longer.

3. According to the national standard, function that four minute countdown after feeding is added in the machine.

![]() 4. The RS232 interface is available to be connected to the computer to output data(optional).

4. The RS232 interface is available to be connected to the computer to output data(optional).

5. The last test conditions can be directly displayed after boot-strap to avoid users resetting test parameters each time ,reducing the workload of the operators.

6. The maximum temperature can be up to 450~500℃。(optional, special instructions when ordering).

7. After long time test of strong corrosive plastic such as full fluorine plastic, the accuracy of the instrument is non-destructive.

8. Meeting standards:ISO 1133, ASTM D1238, GB/T3682

Product applications

This kind of instrument can be used to test the melt flow rate(MFR) figures of all kinds of plastic and resin in the viscous flow state. It is not only suitable for the high melting temperature engineering plastics of polycarbonate, polyarylsulfone , fluorine plastic and nylon but also suitable for some other low temperature plastic products which are made up of polyethylene(PE), polystyrene(PS), polypropylene(PP), ABS resin, polyoxymethylene(POM) and polycarbonate. So it is not only widely used in the plastic production, petroleum and chemical industry but also in the relevant institutions such as scientific research units and the community inspection departments.

The melt flow rate instrument is suitable for measuring the thermoplastic melt mass flow rate following the determination in the standard ”GB/T3682-2000 thermoplastic melt mass and volume flow rate measurement”. The standard is equivalent to the requirement in the ISO 1133:1997 and can meet the ASTM D1238 test.

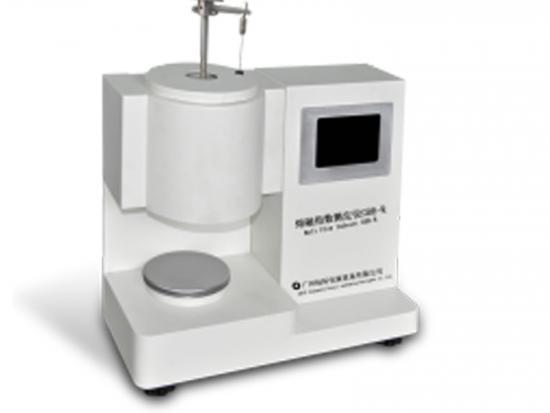

Considering the beautiful appearance and convenient operation ,the desktop structure of the melt flow rate instrument makes the equipment performance reliably and stably. Besides, the high-precision control instrument using fuzzy PID algorithm for temperature control has the feature of high sampling precision and high speed control.

Product features

1、Fast heating speed,minimal overshoot

2、High precision of constant temperature

3、A constant temperature can be quickly restored after packing .

4、Test parameter calibration and correction is convenient.

5、Manual and automatic cutting test methods are optional.

6、The instrument is equipped with LCD working platform.

7、The test results are automatically printed putout equipped with a printer.

|

Display method |

7-inch touch screen + connectable computer software |

|

Heating zone |

Multi-stage (2-stage) temperature control method, 2 sets of platinum resistance sensors, 2 heating zone for independent temperature control, high-precision intelligent PID control, the heating slope or heating speed is adjustable, gradient of 0-70mm interval ±1°C |

|

Test method |

MFR+MVR |

|

Temperature curve display |

YES |

|

Output method |

Micro printer or computer software output report |

|

Die |

A standard 2.095mm die |

|

Weight level |

level 8 (0.325㎏、1.2㎏、2.16㎏、3.8㎏、5.0㎏、10.0㎏、12.5kg、21.6k g) |

|

Weight loading method |

Automatically Loaded Weights |

|

Cutting method |

Manual + automatic cutting |

|

MVR Displacement Accuracy |

0.01mm (different measurement intervals can be set to meet the latest international standards) |

|

Cleaning mode |

Die manual cleaning + barrel manual cleaning |

Specifications

|

Items |

Melt flow index tester |

|

Temperature Range |

RT-450℃ |

|

Temperature drift |

4hour, ≤0.5℃ |

|

Display Device |

Keystroke controlled |

|

Temperature fluctuation |

± 0.2℃ |

|

Temperature uniformity of 10mm-70mm above the die |

± 1℃ |

|

Temperature display resolution |

0.1℃ |

|

Time display resolution |

0.1S |

|

Cutting timing range |

1-999S adjustable |

|

Mouth mold diameter |

Φ2.095±0.005mm ( Mouth Radius : 1.05 mm + 0.005 ) |

|

Discharge hole length |

8.000 ± 0.025mm |

|

Piston rod diameter |

9.474 ± 0.007mm |

|

Piston rod length |

6.35 ± 0.13mm |

|

Loading container diameter |

Φ9.550 ± 0.007mm |

|

Test range |

0.1-150g / 10min |

|

Farmar precision |

± 0.5% |

|

Displacement measuring encoder |

Omron photoelectric rotary encoder |

|

Testing scope of mass method |

0.1-150g /10min |

|

Test range by volumetric method |

50-5000cm³/10min(It can measure up to 5000 cm3/10min by using the plugging die) |

|

Output way |

Micro automatic printout |

|

Blanking way |

Hand automatic cutting can be switched |

|

Test farmar ( weights) |

total 8 grades, 8 sets of weights |

|

Power supply |

AC220V±10% 50HZ |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar