Introduction

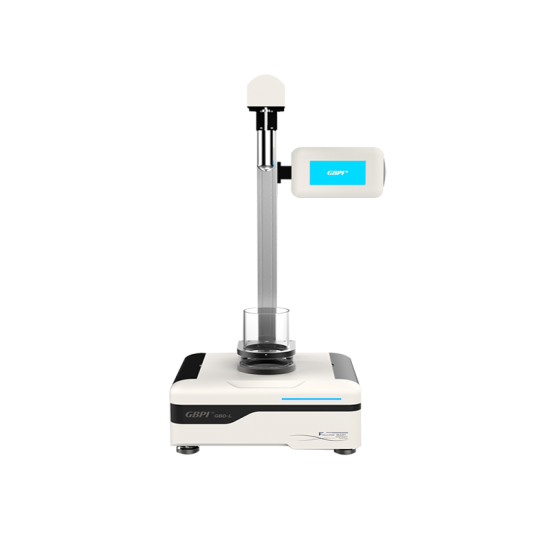

Battery Diaphragm Gas Permeability Tester N600E is designed and developed according to GB/T 36363-2018 and other standards. It adopts the test principle of differential pressure method and is professionally used for testing the air permeability of battery separators, breathable membranes and related polymer materials.

Test principle

In the environment of test temperature, humidity and normal pressure, under the pressure of 1.21kPa applied by the test instrument, the time required for 100mL air to pass through the diaphragm with an area of 6.45 cm2.

Standard

ISO 5636-5, TAPPI T460, GB/T 36363

Specification

|

Test range |

60~12000 s/100mL |

|

Resolution |

0.1 s/100mL |

|

Pressure range |

0~3 KPa |

|

Pressure resolution |

0.001 kPa |

|

Test area |

6.45cm2 |

|

Sample size |

>50 mm×50 mm |

|

Instrument Size |

450 mm×400 mm×300 mm |

|

Power |

100W |

|

Power supply |

110~250 VAC, 50~60 Hz |

Features

The pressure difference of the instrument is adjustable in the range of 0~3 kPa, with an accuracy of 0.001 kPa, which fully meets the test pressure difference requirements of different methods;

The instrument supports s/100mL and um/(Pa.s) multi-unit display.

The test range can be customized according to different sample requirements.

The host is equipped with a color touch screen, no need for an external computer, and the air permeability of the sample can be observed in real time;

Built-in micro-printer, which can print test report in real time;

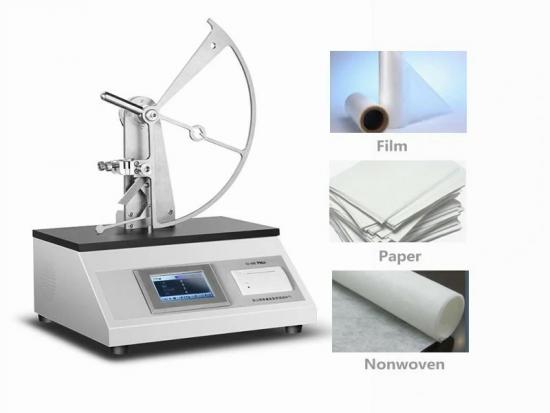

Application

|

|

Lithium Ion Battery |

Polyolefin separator for lithium ion battery, coated polyolefin separator for lithium ion battery or separator for lithium ion battery using other materials |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar