Standards

ASTM D645, ASTM D374, ASTM D1777, ASTM F2251, TAPPI T411, DIN 53105, DIN 53353, JIS K6250, JIS K6328, JIS K6783, JIS Z1702, BS 3983, BS 4817

GB/T 6672, GB/T 451.3, GB/T 6547, ISO 4593, ISO 534, ISO 3034

ASTM D374 - Standard Test Methods for Thickness of Solid Electrical Insulation

ASTM D1777 - Standard Test Method for Thickness of Textile Materials

ASTM D3652 - Standard Test Method for Thickness of Pressure-Sensitive Tapes

ASTM D6988 - Standard Guide for Determination of Thickness of Plastic Film Test Specimens

ASTM F2251 - Standard Test Method for Thickness Measurement of Flexible Packaging Material

ISO 4593 - Plastics -- Film and sheeting -- Determination of thickness by mechanical scanning

ISO 534 - Paper and board -- Determination of thickness, density and specific volume

ISO 3034 - Corrugated fibreboard -- Determination of single sheet thickness

ISO 5084 - Textiles -- Determination of thickness of textiles and textile products

ISO 12625-3 - Tissue paper and tissue products -- Part 3: Determination of thickness, bulking thickness and apparent bulk density and bulk

TAPPI T411 - Thickness (caliper) of paper, paperboard, and combinedboard

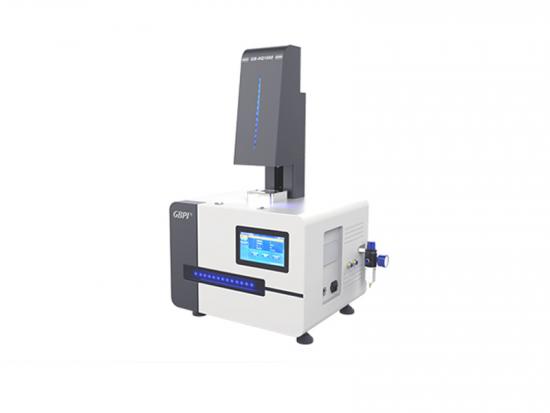

Technical parameters:

| Item | Technical Parameters |

| Measurement Range | 0~6 mm |

| Resolution | 0.1 µm |

| Sampling Spacing | 0~500 mm |

| Number of Measurement Points | 1~30 points |

| Measuring Force | 0.7 N |

| Measuring Head | Φ6 mm |

| Power Supply | AC 220 V, 50 Hz |

| Dimensions | 410 mm×310 mm×340 mm |

| Power Rating | 100 W |

| Weight | 19.5 kg |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar