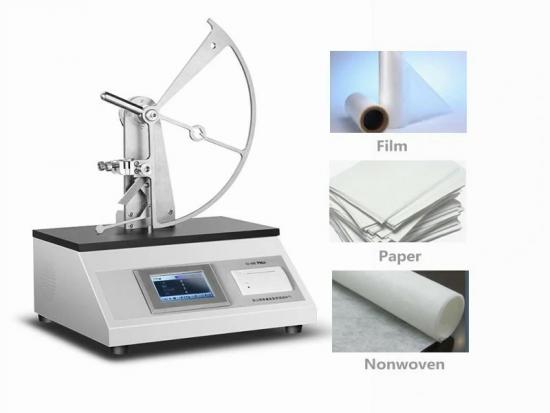

Application

To test the air permeability of the paper and cardboard.

Operating principle

Gurley Method:To measure the time taken to pass 100 ml of gas at a constant pressure difference of 1.23 kpa.

Schopper-Riegler Method: Select the appropriate test duration and determine the air flow rate through the sample by measuring the volume under the constant pressure difference of 1.00kPa ± 0.01kPa or 2.50 ± 0.01kPa

Bendtsen method:At a constant pressure difference of 1.47kPa, the air flow through the test surface was recorded after clamping for 5s.

Standards

ISO 5636-5:2003, ISO 5636-2:1984, ISO 5636-3:2013, TAPPI T460, GB/T 458-2008, SJ/T 10171-2016

Specifications

|

Test Range |

0.1~10 μm/(Pa.s) |

|

Resolution |

0.001 μm/(Pa.s) |

|

Pressure difference range |

0~3 kPa |

|

Pressure resolution |

0.001kPa |

|

Test area |

6.42cm2 or 10.0cm2 |

|

Sample size |

>50 mm×50 mm |

|

Instrument size |

L×W×H: 450 mm×400 mm×300 mm |

|

Power |

100 W |

|

Power supply |

110~250 VAC, 50~60 Hz |

Integrate Gurley's method, Schober's method, and Bengtsen's method into one machine for users to choose freely to meet the testing needs of different users;

The pressure difference of the instrument is adjustable in the range of 0~3 kPa, with an accuracy of 0.001 kPa, fully meeting the test pressure difference requirements of the three methods;

The test area can be freely converted between 10.0 cm2 and 6.42 cm2 by changing the fixture;

The sealing of the instrument is good, and the air leakage does not exceed 1.0 mL/h;

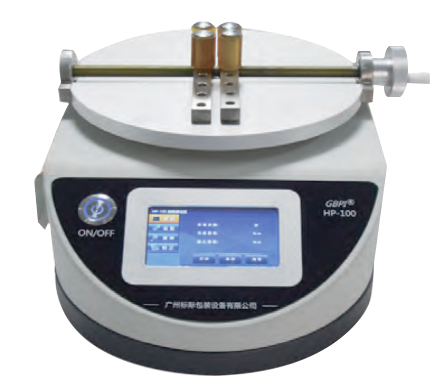

The host is equipped with a color touch screen, no external computer is needed, and the air permeability of the sample can be observed in real time;

Built-in micro printer, which can print test reports in real time.

Application

|

|

Insulating paper |

Measurement of air permeability of transformer insulation cardboard, green shell paper, cable paper, etc. |

|

|

Wrapping paper |

Determination of air permeability of kraft paper, paper bag paper, food packaging paper, moisture-proof paper, paraffin paper, etc. |

|

|

Fiber paper |

Determination of air permeability of wound paper, impregnated paper, laminate, capacitor paper, high temperature fiber paper, etc. |

|

|

Filter paper |

Air permeability measurement of industrial filter cloth (filter paper), qualitative filter paper, quantitative filter paper, etc. |

|

|

Other |

Alkaline battery separators (nylon felt, non-woven fabrics, tissue paper and other microporous membranes) and other materials. |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar