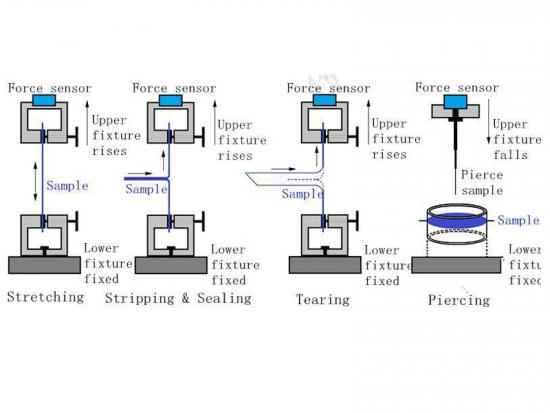

Flexible Packaging film Tensile properties indicate how the material will react to forces being applied in tension. A tensiletest, also known as tension test, is a fundamental mechanical test where a carefully preparedspecimen is loaded in a very controlled manner while measuring the applied load and theelongation of the specimen over some distance. Tensile tests are used to determine the modulusof elasticity, elastic limit, elongation, proportional limit, and reduction in area, tensile strength,yield point, yield strength and other tensile properties.Tensile properties of thin film used in Flexible packaging are tested comply to ASTMD882–Standard Test Method for Tensile Properties of Thin Plastic Sheeting, standard ASTM D828Standard Test Method for Tensile Properties of Paper and Paperboard Using Constant-Rate-of-Elongation Apparatus and ISO 37 Rubber, vulcanized or thermoplastic —Determination of tensile stress-strain properties.The most common testing machine used in tensile testing is the universal testing machine. Themachine must have the proper capabilities for the test specimen being tested.

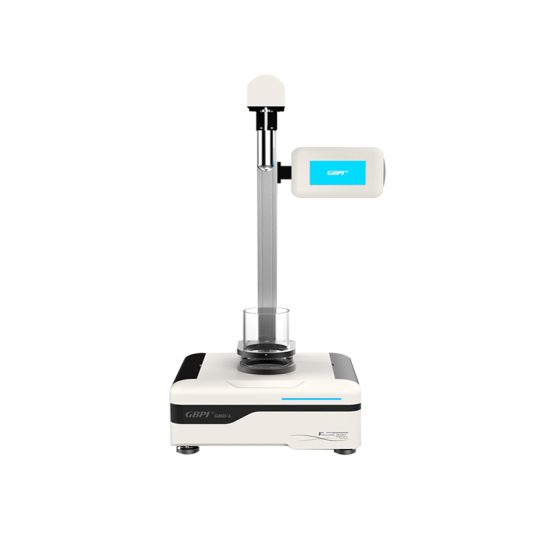

GBPI GBH-1 Electronic Tensile Tester with force range 0~500N (0~3000N optional ), 1500% elongation;force accuracy within ±0.5% of the displayed value (grade 0.5) and test speed 0-500mm/min (infinitely variable speeds)

Technical Parameters

1. Versatile functions, interface and operation modes; multiple parameters setting.

2. Computer controlled, online display of test result, auto data storage and analysis, multiple curves record, zoom in/out, computer print.

3. Modularized, can extend function.

4. Control module can be built in (for simplistic structure and saving space), or be installed external (for easy upgrade, maintenance, and independent working without computer)

5. 3 levels of security protection.

6. High sampling speed (100 times/s)

7. Core part is imported, with high precision and durable.

8. Table standing design for sitting operation, easy and comfortable.

9. Various clips optional for different test purposes.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar