GBPI Spectrophotometer (Core Technology)

GBPI Spectrophotometer (Core Technology)

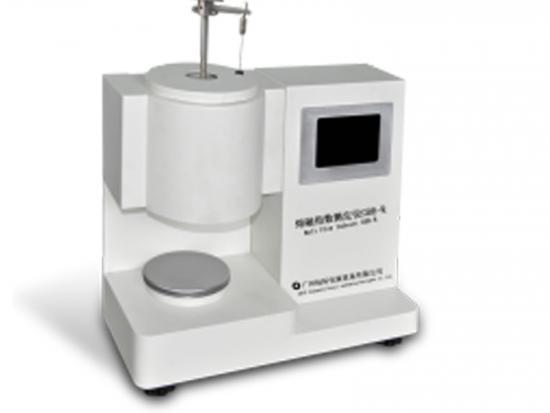

Introduction

GBPI haze meter can easily achieve ASTM D1003 non-compensation method, ISO 13468 compensation method, full light transmittance,haze test.Open sample bin can be vertically and horizontally tested to accommodate more samples to be tested.The YH1200 haze meter uses a PD array detector to meet the CIE V(λ)2 degree visual response. The compensation method can be used to measure the light transmittance and haze with high precision and repeatability.

Technical Advantage

1.Double standard ISO&ASTM

Able to meet the test standard requirements of different users, in accordance with ASTM D1003/1044,ISO 13468,ISO 14782,GB/T 2410,JJF 1303-2011,CIE 15.2,JIS K7105,JIS K7361,JIS K 7136

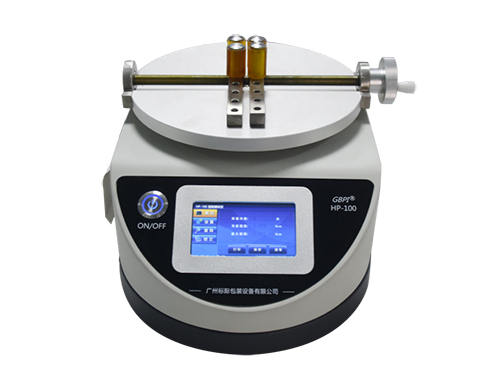

2.Easy to operate, faster and more accurate measurement

The YH1200 haze meter is equipped with a large-size touch screen for easy operation.With a PD array detector, CIE V(λ)2 degree visual response enables high precision and repeatable transmittance and fog measurements.USB data output device for docking with laboratory system.

3.Dynamic measurement

Independent light source detector and temperature sensor, constantly monitor light source and environmental change, ensure the reliability of test data.

4.With compensation port, so that the measurement data more accurate

Meet ASTM D1003 non-compensation method, ISO 13468 compensation method, full light transmittance, fog test, provide more accurate test results.

5.Easy to measure and widely applicable to samples

Open measuring area, vertical and horizontal testing, suitable for more samples to be tested.

6.Quality control software

It provides powerful software for measuring and analyzing fog and light transmittance, which is suitable for quality monitoring and tabulated management of fog and light transmittance data in various industries.The management of users will be digitized at the PC end, the difference of fog and light transmittance will be compared, and the test report form will be generated to facilitate customer customization and management.

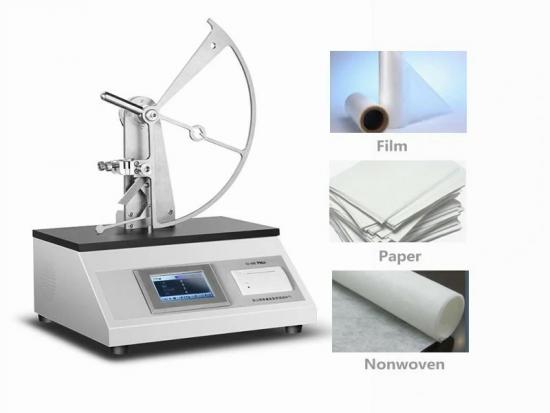

Application

YH1200 haze meter is widely used in glass processing, plastic processing, film processing, screen processing, packaging industry, liquid pharmaceutical analysis and other aspects.

Specification

Product Model

GBPI Haze Meter

Optical Geometry

Transmittance:0/D (Parallel light illumination, diffuse viewing); Conform to the standards: ASTM D1003/1044,ISO 13468,ISO 14782,GB/T 2410,JJF 1303-2011,CIE 15.2,JIS K7105,JIS K7361,JIS K 7136

Characteristic

The instrument can easily achieve ASTM D1003 non-compensation method, full light transmittance,haze test. Open measuring area for vertical and horizontal testing. In glass processing, plastic processing, film, screen processing, packaging and other industries are widely used in transmittance,haze detection.

Integrating Sphere Size

Φ154mm

Light Source

400nm to 700nm, combined LED light

Spectrophotometric Mode

/

Sensor

The PD array detector satisfies CIE V(λ)2 degree visual response

Wavelength Range

/

Wavelength Interval

/

Semiband Width

/

Measurement range

0~100%

Measuring Aperture

Φ20mm/Φ15mm/Φ8mm/Φ4mm(Select a single aperture)

Sample Size

Thickness <170mm

Color Space

/

Color Difference Formula

/

Other Colorimetric Index

Haze(ASTM D1003/1044,ISO13468),Transmittance T(ISO),Transmittance T(ASTM)

Observer Angle

2°

Illuminant

D65,A,C

Displayed Data

PASS/FAIL Result

Measuring Time

About1.5s

Resolution

0.01unit

Repeatability

Φ20mm,within 0.05 (After preheating and calibration of the instrument, standard deviation values of standard haze tablets with a test haze of about 30 for 30 times were taken at intervals of 5s.)

Inter-instrument Error

Φ20mm,with 0.4 (After the instrument is preheated and calibrated, the standard deviation between the standard haze tablet and the reference value is tested at an interval of 5s.)

Dimension

L*W*H=290X211X511mm

Weight

About7.6kg

Power

AC 24V, 3A Power adapter power supply

Illuminant Life Span

5 years, more than 3 million times measurements

Display

7-inch TFT color LCD, Capacitive Touch Screen

Data Port

USB, Print serial port

Data Storage

Standard 1000 pcs,sample 20000 pcs

Language

Simplified Chinese,Traditional Chinese,English

Operating Environment

0~40℃(32~104°F)

Storage Environment

-20~50℃(-4~122°F)

Standard Accessory

Power Adapter, User Guide,Quality Management Software (download from the official website),USB cable,0% calibration box, measuring aperture.

Optional Accessory

Micro-printer,Test fixture, standard haze sheet, foot switch

Note:

The specifications are subject to change without notice.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar