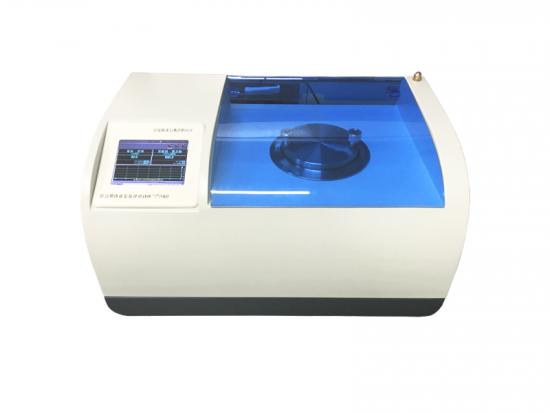

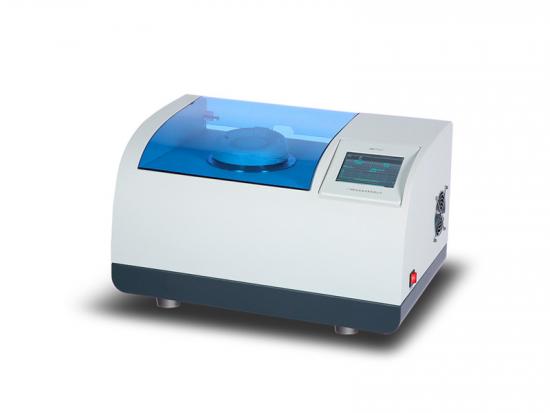

N500 Gas Permeability Analyzer

Applied to:

1)Plastic film, composite film, aluminum foil, aluminized film,etc;

2)Sheet, panel, rubber, ceramics,etc;

3)Packaging containers, such as:glass, bottle, cans, boxes, etc;

4)Expanding application: solar panel, LCD film, contact lenses, medical patch, etc.

Widely used in quality inspection organizations, drug control institutions, research institutes, packaging, thin film, food companies, pharmaceutical enterprises, personal care industry, electronics industry and so on.

Specification

|

Item |

Technical Parameters |

|

Testing range |

0.02~50000 cm3/(m2·24h·0.1MPa) Max possibility by expanding the volume: 600000 cm3/(m2·24h·0.1MPa) |

|

Test accuracy |

0.001 cm3/(m2·24h·0.1MPa) |

|

Temperature range |

15~60℃ |

|

Temperature accuracy |

±0.1℃ |

|

Vacuum degree |

<20Pa |

|

Vacuum resolution |

0.01Pa |

|

Test pressure |

-0.1~+0.1MPa |

|

Gas supply pressure |

0.2~0.8MPa |

|

Gas port |

1/8 inch |

|

Test gas |

O2,Co2, N2, etc |

|

Test area |

50.24 cm2 |

|

Sample size |

Φ110 mm |

|

Sample thickness |

≤2mm |

|

Instrument size |

1 piece |

|

Instrument size |

680mm×560 mm×340mm |

|

Weight |

70kg |

|

Power |

1000W |

|

Power supply |

AC 220V,50Hz |

Standard:GB/T 1038-2000,ISO 2556-1974,ISO 15105-1-2007,ASTM D1434, YBB 00082003-2015,JIS K7126-1-2006

Features

Accurate and reliable data

With The State Certificate for Gradation of the certified Reference Materials andLicence for Manufacturing Measuring Instruments of the state Reference Materials(GBW(E)130541/2)of Gas Permeability Analyzer approved and issued by General Administration of Quality Supervision, Inspection and Quarantine of the P.R.C. Adopting state reference materials to calibrate and verify the instruments, data reliability up to 100%, with universal temperature and humidity calibration interface and test repeatedly, the dispersion of the same sample test data are less than 10%. Ensure the accuracy, universality and authority of test data.

Simple operation

1)Professional software with simple interface, easy to use and convenient to set test process.

2)Fully-auto operation, one-button test, judge and stop automatically.

3)Programmed auto-control, the experiment status display in real time.

4)Professional test report; can be exported as PDF.

Advanced technology

1)World’s pioneer auto keep pressure difference technology, which can keep pressure difference of two sides of samples automatically (pressure can be adjusted).

2)Temperature control: International advanced electromagnetic technology, program controlled, automatic temperature rise and fall. Precision 0.01℃.

3)Carrying cutting-edge ARM controlling system, can run independently without computer.

High efficiency

1)One independent test chamber with an independent main sensor.

2)With three different test modes of high, medium and lower barriers, can test films with different barrier property.

3)Measurement precise up to 0.01 cm3/(m2·24h·0.1MPa), can test high barrier materials, such as aluminum foil.

4)By adding package-testing accessories, can test gas transmission of various containers such as bag, bottle, can and bowl.

5)Can expand upper limit of test range to 600000cm3/(m2·24h·0.1MPa).

Calibration & Certification

The instrument supports two methods of reference materials and standard gas to certificate and calibrate; Operation is simple, user only need use certified reference materials for normal testing, and then input the test result into the instrument interface to complete calibration.

Reliable and easy-maintenance instrument

1)Imported pressure sensor, with high precise and good performance, can work for a long time.

2)Sensor over-range auto protection.

3)Function modularization, easy to maintain.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar