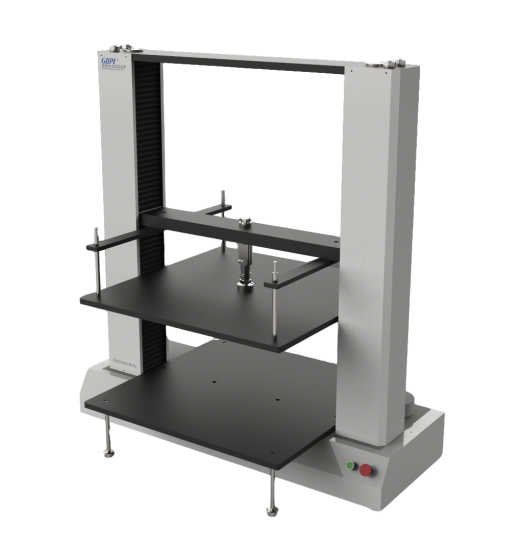

AUTO GQ100 Modified Atmosphere Refrigerator

AUTO GQ100 Modified Atmosphere Refrigerator

The AUTO GQ-100 Modified Atmosphere Refrigerator is meticulously engineered for storage and preservation tests of diverse fruits, vegetables, flowers, seedlings, and more. By harnessing microelectronics technology, it automatically regulates the concentrations of oxygen, nitrogen, carbon dioxide, and ethylene inside the refrigerator, along with temperature and humidity conditions, to achieve outstanding preservation effects. It is an essential and perfect equipment for microbiology, environmental protection, food production, universities, research institutions, and other relevant organizations.

Technical Parameters

Project

Technical Parameter

Gas Measurement Range

O₂: 0%–30%; CO₂: 0%–20%; C₂H₄: 0–220 ppm; Remaining gas: N₂

Gas Testing Accuracy

O₂: 0.01%; CO₂: 0.01%; C₂H₄: 0.1 ppm

Gas Purity Requirement

Purity of O₂, CO₂, N₂, and C₂H₄ ≥ 99.9%

Gas Flow Control

O₂: 0–500 mL/min; CO₂: 0–500 mL/min; N₂: 0–500 mL/min

Temperature Control Range

-5°C–45°C

Chamber Temperature Control Accuracy

±0.5°C

Chamber Humidity Range

Normal–95% RH

Humidity Fluctuation Range

±3% RH

Cooling Capacity

1 HP

Chamber Humidifier Power

50 W

Chamber Lighting System Power

10 W

Material

Colored steel plate

Dimensions

889 mm × 1285 mm × 1750 mm

Total Machine Power

1 KW

Number/Volume of Test Chambers

1 chamber/100 L

Power Supply

AC 220V

Application

Fruit and vegetable storage and preservation

It is suitable for the storage and preservation test of various domestic and imported fruits and vegetables.

Storage and preservation of meat and seafood

It is suitable for storage and preservation test of various pork, beef, mutton and other meat and seafood products such as fish, shrimp, crab, etc.

Baked food storage and preservation

It is suitable for the storage and preservation test of various bakery products such as bread, cakes and biscuits.

Storage and preservation of flowers and seedlings

It is suitable for the storage and preservation test of various roses, lilies, phalaenopsis and other flowers and seedlings.

Product features

Three test chambers work independently; Each chamber has its own humidity, flow and concentration of various gases, ethylene removal devices, lighting systems, sterilization systems, and drainage systems.

Built-in microcomputer system, automatic control, and automatic processing of data. Manually switch the cavity to display the temperature and humidity of each cavity, as well as the concentration of oxygen, nitrogen, carbon dioxide, ethylene, and so on.

24 inch 100,000 real color touch screen, can set the parameters of each cavity and control operations respectively; Detailed data and work status are displayed in real time.

Built-in ozone sterilization, manual button sterilization, can set the sterilization time.

Built-in ethylene catalytic removal device and gas displacement pump control ethylene concentration, fast degassing speed.

Imported high-precision sensors to detect various gas concentrations and ethylene concentrations.

The sterilization system adopts ozone sterilization, the manual button for sterilization, automatic control of sterilization time, and automatic stop when the set time is reached.

Temperature control: using heating wire heating, scroll compressor cooling, stable performance, low noise; PID algorithm with solid state relay control, no hard mechanical contacts, long service life, average temperature heating, constant temperature. The temperature control of each chamber adopts unified control, and the temperature of the three chambers is set manually.

Humidity control: high-frequency atomization humidification, the humidification range is large, long-term humidification does not heat, does not affect the cavity temperature; Each chamber humidification system operates independently, automatically humidifies and maintains humidity after setting the humidity.

The inner wall of each cavity is made of stainless steel, the special double-layer glass door, and the shell is made of special color steel plate.

Transparent windows, drainage system anti-condensation, built-in lighting, and self-entry box design.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar