Standards

ASTM D 2063, ASTM D 3198, ASTM D 3474

Technical parameters

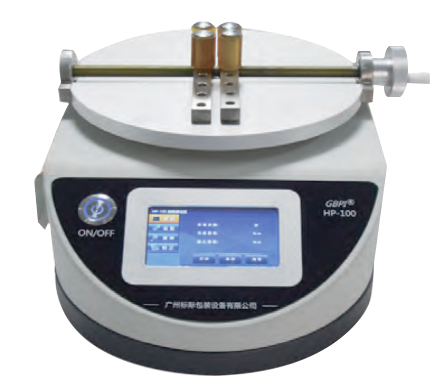

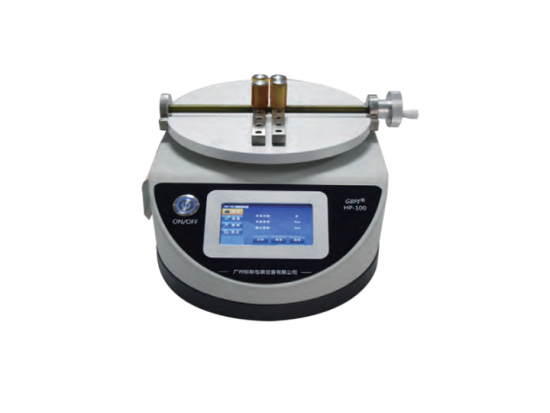

| Item | Technical Parameters |

| Measuring Range | 0 - 20 N·m |

| Measuring Precision | Grade 0.5 |

| Resolution | 0.001 N·m |

| Clamping Range | Φ10 - 200mm |

| Number of Statistical Groups | 10 groups |

| Power Supply | AC220V 50Hz |

| Overall Dimensions | 317mm395mm208mm |

| Net Weight | Approximately 10 KG |

Product Features

high-definition LCD screen display, torque magnitude as torque numbers, easy and precise reading.

has data tracking and holding function.

Three sets of torque units switching function: Lbf-in (pound force-inches), Kgf-cm (kilogram-cm), N-m (Newton-meter).

tester can be used for measuring torque in clockwise and counterclockwise directions, that is, the torque of tightening and loosening parts.

Applications

|

|

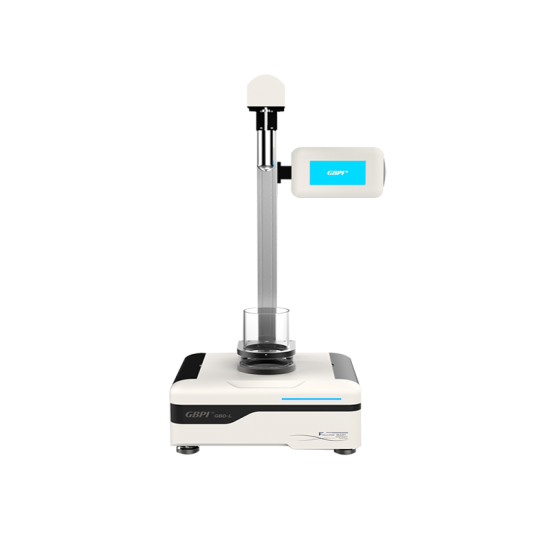

Bottled containers |

Suitable for testing the torque value of locking and opening caps of bottled packaged food and medicine (threaded connection), such as beverage bottles and medicine bottles |

|

|

Insulation bottle, insulation cup products |

Suitable for testing the torque value of locking and opening the lid of thermos bottles and thermos cups (threaded connection) |

|

|

Suction Nozzle Packaging Products |

Suitable for testing the torque value of cap locking and opening of nozzle packaging products |

|

|

Tube packaging products |

For testing the torque value of cap locking and opening of tube packaging products |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar