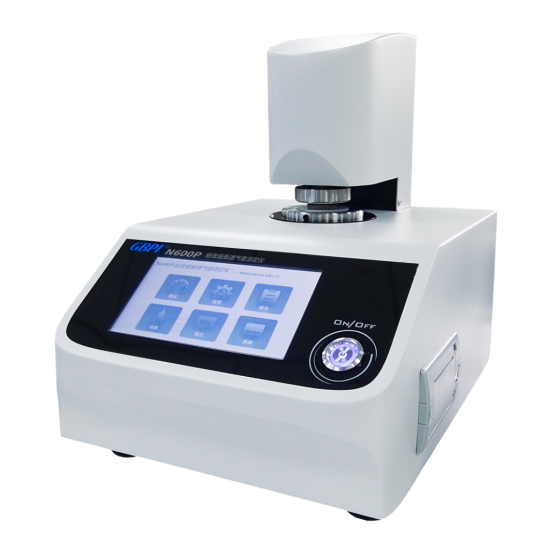

1. Product Introduction

N900 Air permeability analyzer, a blend ofmechanism, electron and software, is high precision experiment-usage testing instrument developed by GB/T5453-1997 Textile--Determination of the permeability of fabrics of air.

Itis applied to test the air permeability of many textile, including technical fabric, non-woven and breathable textile products.

Key components:imported pressure sensor, turbofan, air cylinder, motor

2. Working Principle

Air permeability refers to the performance of air pass through the fabric. Indicate it by the rate of airflow vertically penetrating the test sample in a certain test area, pressure drop and time.

Keeping a pressure difference, test the airflow vertically penetrating the test area of sample in a certain period of time, so as to calculate the air transmission rate. The airflow rate can be calculated directly, or calculated by testing pressure differences between two sides of flow pore.

3. Standard

ISO 4638-1984, ASTM D737-2004(2016), GB/T 5453-1997, ISO 9237-1995, GOST ISO 9237-2013, GB/T 10655-2003, QB/T 2799-2006

4. Technical Specifications

|

Item |

Specifications |

|

Pressure differential measurement range

|

1~4000Pa(pressure drop can be adjusted) |

|

Test range |

1~40000mm/s |

|

Test error |

≤±2% |

|

Sample size |

150mm×150mm |

|

Test area |

5cm2、20 cm2、50 cm2、100 cm2 |

|

Sample thickness |

≤10mm |

5.Instrument Features

1) Cylinder control and fix the sample automatically, quick test.

2) Pressure adjustable; auto measure, auto calculate results.

3) Mainframe configures color touch screen, without external computer, can observe the permeability rate of the sample in real-time.

4) Can test multiple sets of data continuously; can query, delete a group or groups of experimental results, print reports.

5) Professional software, simple interface, easy to operate, display test data (air permeability, variation coefficient and other parameters) in real time, support different unit conversion. ( Test unit: mm/s, l/(dm^2.min), l/(m^2.s), m^3/(m^2.min), m^3/(m^2.h), cfm, cm^3/(cm^2.h), ml/s, ml/min, l/s, l/min)

6) Generate standard test report automatically, details contain sample name, specifications, serial number, the direction of the airflow through the fabric, test area and the pressure drop of the experiment, standard, test dates, and test results (air permeability rate, variation coefficient, 95% confidence interval).

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar