Standards

ASTM D2063, ASTM D3198, ASTD3474, BB/T 0025, BB/T 0034, GB/T 17876

Features

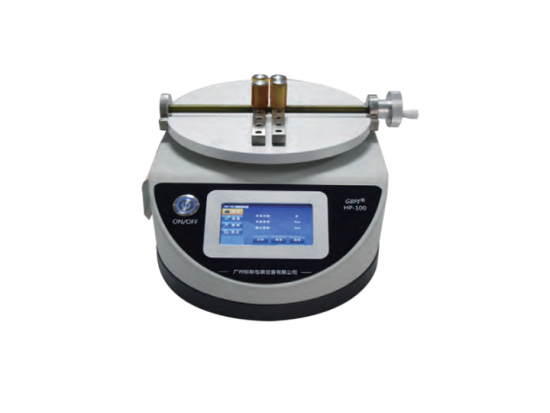

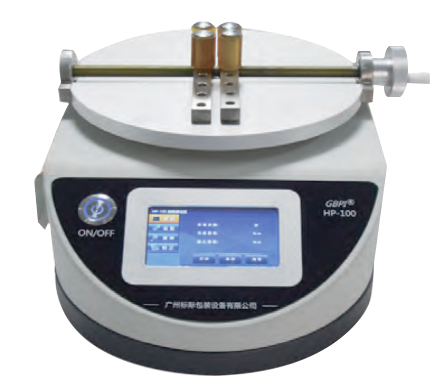

1. LCD display; data tracking and storage.

2. Three torque units options: lbf·in, kgf·cm, N·m.

3. Can move clockwise or anticlockwise, can test screwing locking or unscrewing open.

Specifications

|

Test range |

0.01-10N·m |

|

Test accuracy |

within ±1% |

|

Clipping range |

Ø10~150mm |

|

Instrument size |

410mm×320mm×200mm |

|

Weight |

9.5kg |

Applications

|

|

Bottled containers |

Suitable for testing the torque value of locking and opening caps of bottled packaged food and medicine (threaded connection), such as beverage bottles and medicine bottles |

|

|

Insulation bottle, insulation cup products |

Suitable for testing the torque value of locking and opening the lid of thermos bottles and thermos cups (threaded connection) |

|

|

Suction Nozzle Packaging Products |

Suitable for testing the torque value of cap locking and opening of nozzle packaging products |

|

|

Tube packaging products |

For testing the torque value of cap locking and opening of tube packaging products |

Configuration

Main machine body, clips, force buffer, charging cable

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar