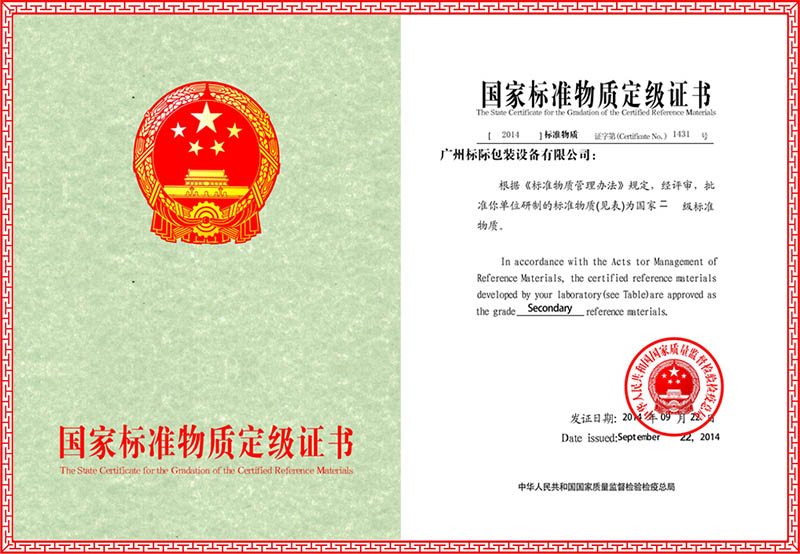

For a long time, there is a blank in the reference materials for packaging testing instruments in the industry. The Measuring Development Plan (2013- 2020) issued by State Council points out that Food safety, clinical laboratory, biological, environmental protection, material science become the focus of research and development of reference materials. Now, the reference materials of gas permeability, water vapor permeability and oxygen permeability produced by GBPI win the affirmation of Grade Secondary Reference Materials. GBPI becomes the first development organization of the reference materials of film permeability. These reference materials are mainly applied to the calibration and inspection of the gas permeability, water vapor permeability and oxygen permeability of packaging of food and drug. Reference Materials plays a very important role in packaging testing.

【Definition】

A substance or material that has been determined to have a sufficiently uniform property value, as a "measuring device" in the analytical measurement industry.

【Function】

Calibrate, adjust and identify instrument and devices.

Product quality control during the production

Examine operation level the analyst

Test characteristic value of substance or material

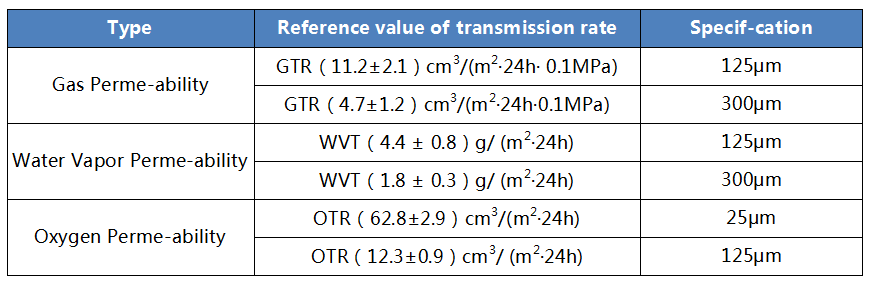

【Reference Value of Reference Materials】

(Note: Reference Materials of Gas Permeability are applicable to all oxygen permeability analyzers which adopt Pressure Differential Method; Reference Materials of Water Vapor Permeability are applicable to all water vapor permeability analyzers which adopt Dish Method; Reference Materials of Oxygen Permeability are applicable to all oxygen permeability analyzers which adopt Coulometric Sensor Method.)

The State Certificate for the Gradation of the Certified Reference Materials

Certificate for Oxygen Permeability

Certificate for Gas Permeability and Water Vapor Permeability

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar