Test Principle

The N500A 2.0 Gas Permeability Tester is designed based on the principle of the differential pressure method. Place the prepared sample between the upper and lower chambers. Use a vacuum pump to evacuate the entire gas circuit system, and then add experimental gas at one atmosphere to the upper chamber to create a constant pressure difference between the upper and lower chambers. Under the action of the pressure gradient, the gas permeates from the upper chamber to the lower chamber through the film. The system can calculate the permeation amount of the experimental sample through the pressure change in the lower chamber. See the following diagram for the differential pressure method schematic:.

Standards

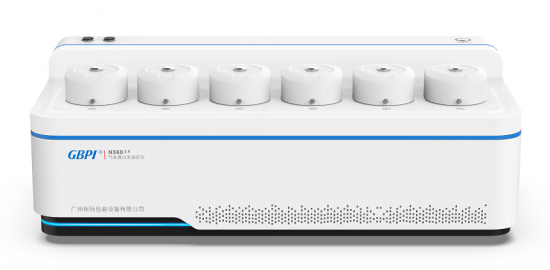

Technical Parameters

| Project | Technical Parameter |

| Testing Range | 0.01~25000 cm³/(m²·24h·0.1MPa) |

| Resolution | 0.0001 cm³/(m²·24 h·0.1 MPa) |

| Temperature Control Range | 15~60℃ |

| Temperature Control Accuracy | ±0.1℃ |

| Vacuum Accuracy | Indicated value ±0.2% |

| Vacuum Degree | <10 Pa |

| Vacuum Resolution | 0.01 Pa |

| Testing Pressure | 0.1 MPa |

| Testing Gases | O₂, CO₂, N₂, etc. |

| Permeation Area | 50.24 cm² |

| Sample Size | Φ110 mm |

| Sample Thickness | ≤2 mm |

| Testing Quantity | 1 piece |

| Overall Dimensions | 380mm585mm345mm |

| Pneumatic Pressure | ≥0.3MPa |

| Power | 450W |

| Power Supply | AC 220 V, 50 Hz |

Features

Application

|

|

Films |

Various plastic films (PP/PET/PE/PVC/BOPP/CPP, etc.), plastic composite films, paper-plastic composite films, metal composite films, co-extruded films, aluminized films, degradable packaging films (PLA/PBAT/PBS etc.) and other membranous materials |

|

|

Sheet |

Solid medical hard sheet (PP/PVC/PTP, etc.), metal composite sheet, rubber sheet and other sheet materials |

|

|

Paper and cardboard |

Coated paper, carbon paper, silicone paper, aluminized paper, paper-aluminum-plastic composite sheet and other paper, cardboard |

|

|

Medicinal patch, warmer patch |

Medical plaster treatment patch, warm patch, dysmenorrhea patch, etc. |

|

|

Hygiene |

Sanitary napkins, pads and other hygiene products |

|

|

Package |

Wine bottles, Coke bottles, peanut oil drums, Tetra Pak packaging, vacuum packaging bags, three-piece cans, cosmetic packaging, toothpaste tubes, jelly cups, yogurt cups, etc. Plastic, rubber, paper, paper-plastic composite, glass, metal bottles Gas transmission rate test of bags, cans, boxes and drums |

|

|

Gases |

Oxygen, carbon dioxide, nitrogen, air, helium, etc. |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar