Test Principle

Standards

GB/T 1038.1, ISO 2556, ISO 15105-1, ASTM D1434, JIS K7126-1, YBB 00082003

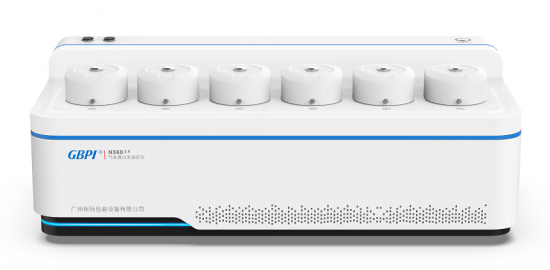

Specifications

| Item | Technical Parameter |

| Testing Range | 0.01~25000 cm³/(m²·24 h·0.1 MPa) |

| Testing up to 600000 cm³/(m²·24h·0.1MPa) by expanding the maximum volume | |

| Resolution | 0.0001 cm³/(m²·24 h·0.1 MPa) |

| Temperature Control Range | 15~60℃ |

| Temperature Control Accuracy | ±0.1℃ |

| Vacuum Degree | <10 Pa |

| Vacuum Accuracy | Indicated value ±0.2% |

| Vacuum Resolution | 0.01 Pa |

| Testing Pressure | 0.1 MPa |

| Testing Gases | O₂, CO₂, N₂, etc. |

| Permeation Area | 50.24 cm² |

| Sample Size | Φ110 mm |

| Sample Thickness | ≤2 mm |

| Number of Samples Tested Simultaneously | 3 pieces |

| Overall Dimensions | 690 mm620 mm390 mm |

| Weight | 55 kg |

| Power | 750 W |

| Power Supply | AC 220 V, 50 Hz |

Application

|

|

Films |

Various plastic films (PP/PET/PE/PVC/BOPP/CPP, etc.), plastic composite films, paper-plastic composite films, metal composite films, co-extruded films, aluminized films, degradable packaging films (PLA/PBAT/PBS etc.) and other membranous materials |

|

|

Sheet |

Solid medical hard sheet (PP/PVC/PTP, etc.), metal composite sheet, rubber sheet and other sheet materials |

|

|

Paper and cardboard |

Coated paper, carbon paper, silicone paper, aluminized paper, paper-aluminum-plastic composite sheet and other paper, cardboard |

|

|

Medicinal patch, warmer patch |

Medical plaster treatment patch, warm patch, dysmenorrhea patch, etc. |

|

|

Hygiene |

Sanitary napkins, pads and other hygiene products |

|

|

Package |

Wine bottles, Coke bottles, peanut oil drums, Tetra Pak packaging, vacuum packaging bags, three-piece cans, cosmetic packaging, toothpaste tubes, jelly cups, yogurt cups, etc. Plastic, rubber, paper, paper-plastic composite, glass, metal bottles Gas transmission rate test of bags, cans, boxes and drums |

|

|

Gases |

Oxygen, carbon dioxide, nitrogen, air, helium, etc. |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar