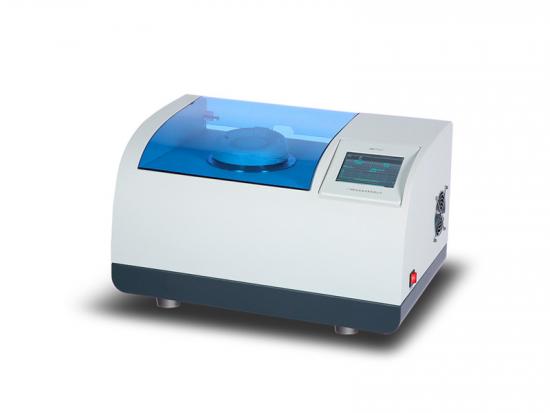

Heat Seal Tester GBB-A1

Introduction

Heat sealing performance is the most important performance of plastic packaging films. GBB-A1 heat sealing instrument can accurately measure the suitable heat sealing temperature range, heat sealing speed, heat sealing pressure, etc. of plastic film substrates, flexible packaging composite films, coated paper, aluminum foil and other heat sealing composites. It is suitable for use in scientific research and teaching experiments of various plastic film, food, and pharmaceutical manufacturers for product quality control and testing institutions, and schools.

Standard

ASTM F 2029

Specification

Item

Technical parameters

Temperature range

Room temperature~250℃

Temperature precision

±0.1℃

Seal time range

0.1s~99h 59min 59.9s

Pressure range

0.1~0.8MPa

Heat seal area

Upper and lower bar: 300mm × 10mm, smooth surface;

(lower bar has silicone pad as buffer)

Heat seal method

Two ways: automatic or manual, external air cylinder

Power supply

AC220V 50Hz

Instrument size

480(L)mm×330(B)mm×570(H)mm

Features

(1) Advanced configuration and technological advancement

Equipped with a high-precision temperature transmitter to accurately ensure temperature stability and accuracy of experimental data.

The core parts are imported components, which are more precise and durable.

The temperature control of the upper and lower sealing knives is independent and can be set separately. The heat sealing head adopts aluminum potting uniform temperature heating tube.

Anti-scald safety design can effectively ensure the safety of users.

Uses compressed air, pneumatic drive, and adopts a bottom-mounted dual-cylinder synchronous circuit design.

The equipment adopts digital P.I.D. temperature control to control the temperature more accurately; the temperature sensor is easy to calibrate.

Pressure detection, touch screen displays the current temperature of the upper and lower sealing knives, heat sealing temperature, heat sealing pressure, and heat sealing time, making it convenient for customers to set parameters according to the sample.

It has two working modes: automatic and manual, and can also be tested using foot pedal.

(2) Easy to operate

Professional software support, the software interface is simple and clear, easy to operate, and the test is convenient and fast. (optional)

Fully automatic operation, one-button automatic operation, continuous operation, reducing operating time and improving efficiency.

The host is equipped with a color touch screen, no external computer is needed, and you can freely test and conduct experiments.

(3) Permission management and data tracking (optional)

A user name and password are required to log in to the software to ensure the security and validity of the account and experimental data.

Users are divided into administrator, operator, observer and other levels, which can be set according to actual needs.

Administrators can adjust permissions at various levels; such as increasing and decreasing system control items at a certain level.

It has audit tracking function (system audit trail, project operation audit trail, method audit trail), and every data change is recorded; ensuring the security and integrity of test data.

Equipped with advanced user management functions, you can manage multiple users, modify user names, passwords, permissions, etc. to meet more customer needs.

(4) Professionalism

The shape, size and smoothness of the sealing knife’s heat seal can be customized.

The sealing knife can be upgraded with anti-sticking function.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar