Introduction

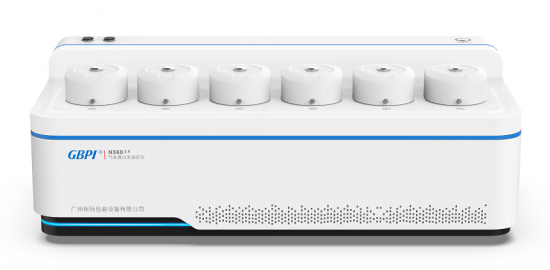

This model has an integrated system design of water bath evaporation, heating, drying, cooling, and constant temperature weighing. The test process is fully automated without manual participation.

It is suitable for testing the overall migration (non-volatile matter, evaporation residue) and other items in the fields of purified water, pharmaceutical packaging materials, food packaging, cigarette tipping paper and chemical reagents.

It can also be applied to the water content, loss on drying and other items of solid samples, and the total dissolved solid content test in water quality testing.

Test principle

- Put the solution to be tested into the solvent storage dish of the automatic feeding system, and the empty cup is heated, cooled and weighed at the set temperature.

- Repeat the steps until a constant weight value is reached.

- Evaporate to dryness on a water bath below the boiling point of the soaking liquid. The cavity is heated to 105°C, dried and cooled.

-After the evaporating dish is cooled, the constant weight is judged with a balance (sensitivity is 0.01 mg), and the experiment is terminated to meet the constant weight requirement of the project.

Standard

|

Purified water |

"Purified water" in "Chinese Pharmacopoeia", "European Pharmacopoeia" EP9.0 WATER, PURIFIED |

|

pharmaceutical packaging materials |

"National Standards for Pharmaceutical Packaging Materials" Non-volatile Matter Items in Dissolution Test |

|

Food packaging materials |

GB 31604.8-2016、EN 1186-3:2002 method A、Standards and Specifications for Utensils, Containers and Packages of Korea Ministry of Health and Welfare chapter IV 2-8 |

|

Chemical reagent |

GB/T 9740-2008、ISO759 |

|

Water quality testing |

GB 8538-2016、DZT0064.9-2021、GBT 14415-2007、GBT5750.4-2006 |

|

Solid sample |

“Chinese Pharmacopoeia four "extracts" and "loss on drying" items, "US Pharmacopoeia"USP40-NF35<921> WATER DETERMINATION |

Specifications

|

Item

|

Technical parameters |

|

Test range |

0 g~80 g |

|

Resolution |

0.01 mg |

|

Scale parameters |

0 g~220g |

|

Constant weight deviation |

0.3 mg,adjustable |

|

Temperature control range of water bath |

Room temperature~100℃ |

|

Temperature control range of heating chamber |

Room temperature~125℃ |

|

Temperature precision |

±0.5℃ |

|

Quantity of samples |

36 |

|

Evaporating dish volume |

50 ml or 100 ml(optional) |

|

Air source interface size |

Φ8 mm |

|

Dimensions |

L×W×H:1200mm*850mm*1335mm |

|

Power |

220V,50Hz |

|

Rated power |

7000 W |

|

Operating system |

Windows 10 Pro Edition 64-bit |

Features

- Cool and hot dual cavity integrated control system, automatic upgraded

It has the integrated system design of water bath evaporation, drying, cooling and constant weight, test automation, high efficiency and precision.

Automatic feeding mechanical design, pneumatic valve control feeding, the residual amount is less than 0.1 mL, the test does not need to wait and manual duty.

The cavity has a built-in water bath, which can automatically detect the water level through the liquid level sensor, automatically add water to replenish water and drain, and automatically control the temperature of the water bath.

- High-precision imported balance, isolation protection design

There are 3 built-in high-precision imported balances with a resolution of 0.01 mg, and the 2-round drying process can reach a constant weight of 0.3 mg.

The balance is placed in a fixed and stable protective cover with a water circulation compartment. When performing weighing, the temperature and humidity are stable.

- Meet high-throughput, high-availability testing needs

The instrument is equipped with 36 test stations with independent data, which can meet the needs of high-throughput testing.

The sample to be tested can be purified water or an organic solvent such as n-hexane, ethanol, acetic acid, and chloroform.

- Cooling recovery system, efficient solvent recovery

The built-in circulating water cooling pump continuously supplies circulating water to keep the cavity low temperature. Efficient and environmentally friendly, it can be cooled to room temperature within 30 minutes.

Equipped with a solvent recovery bottle, the solvent recovery rate is over 90%.

- Smart operating system, global certification

Real-time display of weighing data, temperature curve, humidity curve, real-time storage of temperature and humidity, weighing data, easy to query.

According to GMP appendix computer system design, test process parameters are flexibly set to meet different standard requirements.

It has the function of audit trail (log tracking, test tracking), which can meet the needs of data traceability. System permissions can be set.

Supports data output in multiple formats, supports electronic signatures, and submits audit reports online

Application

|

|

Purified Water |

Suitable for testing the non-volatile content of purified water and sterile water for injection in the pharmaceutical industry |

|

|

Pharmaceutical Packaging Materials |

Suitable for the test of non-volatile matter items in the dissolution test of plastic and rubber pharmaceutical packaging materials |

|

|

Food Packaging Materials |

Suitable for various food utensils, containers and food packaging films, cans or other various food tools, pipes and other products made of polyethylene, polystyrene, polypropylene, perchlorinated vinyl resin as raw materials in different food simulants. Determination of total migration after immersion |

|

|

Cigarette Pack Materials |

Suitable for total migration test of cigarette tipping paper soaking solution |

|

|

Chemical Reagent |

Suitable for the evaporation residue test of chemical reagents, such as ethanol, acetic acid, n-hexane, chloroform and other organic solvents whose boiling point is lower than 100℃ |

|

|

Domestic Water and Drinking Water, Industrial Water, Sewage |

Suitable for the total dissolved solids test of drinking water, drinking natural mineral water, groundwater, drinking water, swimming pool water, urban sewage, industrial boiler water, etc |

|

|

Solid Samples, Pharmaceutical Particles |

Suitable for loss on drying, dry content or moisture testing of solid samples, such as hollow capsules, noncrystalline cellulose and other pharmaceuticals or other solid particles |

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar