Standards

GB/T 15717

Features

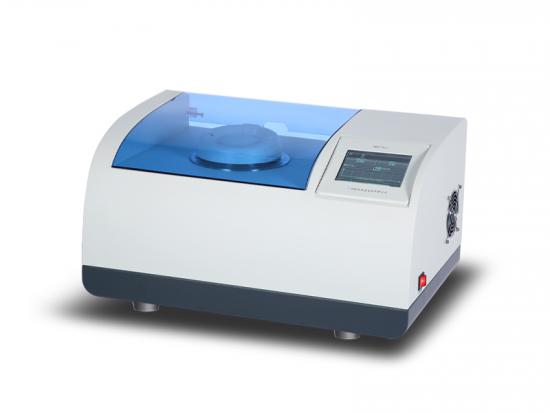

Advanced circuit design assures the accuracy and stability of the test results.

Adopt single-chip microcomputer to catch information, deal with data and control actions. With automatically report communication anomaly.

Microcomputer controlling brings to fast processing speed, precise control, reliable safety and intelligent operation.

Color LED touch screen, friendly man-machine interface allows users to check the data and test results quickly and visually.

High precision contact testing method, reaching a high test accuracy of ±0.001Ω.

Real time display of resistance value (maximum, minimum, average) and thickness (maximum, minimum, average).

Configured with micro printer, which can quickly print out square resistance (maximum, minimum, average), thickness (maximum, minimum, average), and evenness.

Based on actual demands, users can set number of test times to directly get the thickness result.

Specifications

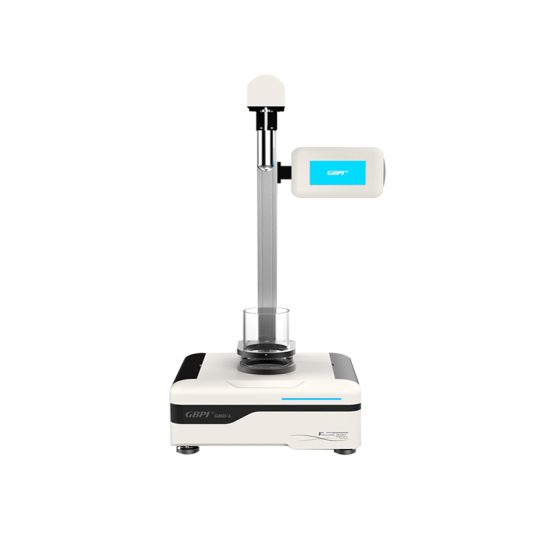

Thickness test range: 50-1200A ̇

Block resistance test range: 0.1-29.999Ω

Block resistance test resolution: 0.001Ω

Test precision: ±0.5%Fs

Variability of the indicated values: <0.1%

Test sample size: 300mmX100mm

Fixture accuracy: ±0.1mm

Coating metal type: Aluminum, copper, nickel, silver...

Instrument size: 300mm×300mm×150mm

Power supply: AC 220V, 50Hz

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar