Almost all foodstuffs consumed today are supplied encased in some form of packaging. By forming a barrier between the food and the environment, packaging materials maintain product quality and safety during shipping and storage. Packaging also protects the food from other packaging materials that may have desirable physical properties but are notorious sources of contamination, like recycled paperboard The types of packaging range from a simple, thin coating of foodgrade wax to complex multi-layered systems that combine paper, plastic and metallic components with adhesives.

However important the packaging is to maintaining the food quality and shelf-life, packaging materials are also a well-known source of contamination when they leach undesirable compounds into the food they are intended to protect. These compounds can be toxins and pose significant health hazards. The etiology of the contamination reveals that the manufacturing process used to make the package materials, adhesives that hold multi-layer packaging together, and the varnishes, inks and dyes applied to the finished package can all be sources of leachables or extractables that end up in the food. Solvents derived from these sources are a major contamination class and are of primary concern to food analysts.

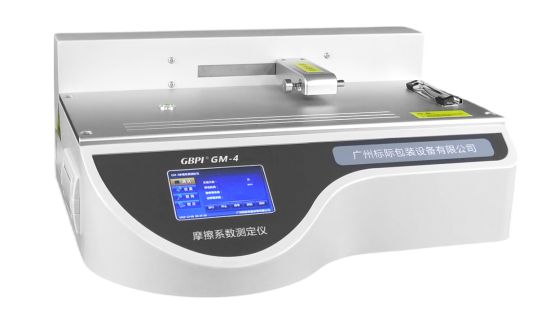

GBPI Design and Manufacture Gas Chromatography GC9802 for our flexible pacakging material factory to help them improve their printing laminating film residual solvents testing.

GC9802 Gas Chromatography Application

To test the smell and solvent residues of printed packaging materials; test the quality and purity of the solvent.

GC9802 solvent residues testing Working principle

Sample of gas, liquid or solid is processed and passes through vaporizing chamber, brought to chromatographic column separation system. Carried by nitrogen, the sample mixture passes and contacts the chromatographic column, and the composition components of the mixture are separated by chromatographic column. Then every separated component is brought to the detector system, and transformed by the detector to equivalent electronic signal, which is collected and recorded as data, so as to make qualitative and quantitative analysis of the components of the sample mixture.

We GBPI not only supply Gas Chromatography Machine but also supply Solvent Residues Testing service in our CNAS Laboratory.Wecome customers to send us samples to testing your printing film residual solvents!

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar