Automatic Rotary Pouch Spout inserting and Sealing Machine GF-1600H

Main Specification

|

1.Spout Type |

Doypack bags, three-side sealing bags, accordion bags, special bags |

|

2.Bag Size |

Max Sealing width: 60~120mm Max Sealing length: 70~230mm |

|

3. Material Type |

Bag: In-layer PE, in-layer PP Spout: PE, PP |

|

4.Spout size |

Caliber 8.5mm(normal), Caliber 10 mm |

|

5. Machine Speed |

30-120 pcs/ min ( Customized ,According To Material & Operating) |

|

6.Heat sealing cutter |

Preheat: 1 group Heat sealing: 4 Group Cooling: 1 group

|

|

7.Power |

13KW

|

|

8.Electric source |

380V, in three-phase four-wire system |

|

9.Machine size |

about 290cm(width) x 270cm(length) x 220cm(hight) |

|

10.Weight

|

2500kg

|

Main Components

|

No. |

Name |

Brand |

|

1 |

Servo motor |

Made in China |

|

2 |

Frequency transformer |

Omron |

|

3 |

PLC |

Omron |

|

4 |

Magnetic switch |

SMC |

|

5 |

Photoelectric switch |

KEYENCE/Omron |

|

6 |

Pneumatic component |

SMC/AIRTAC |

|

7 |

Temperature control module |

Omron |

|

8 |

Slitter |

DEX |

|

9 |

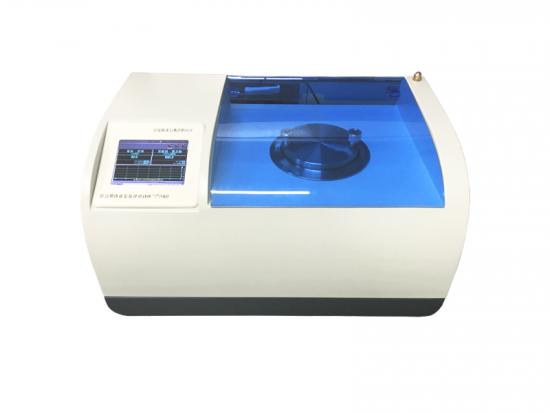

LCD touch screen |

Omron |

Configuration

|

No. |

Name |

Quantity |

|

1 |

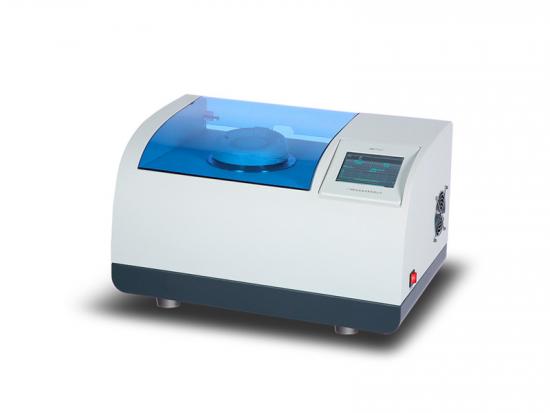

Spout sealing machine |

1 set |

|

2 |

Vibrating disk |

2 sets |

|

3 |

Sealing blade |

6 sets |

|

4 |

Bag putting rack |

1 set |

|

5 |

Bag collecting rack |

1 set |

|

6 |

Installation tools |

1 set |

|

7 |

Specification (User Manual) |

1 set |

Mechanical Structure

|

1.Control cabinet |

PLC, Power, Display, Leakage Protection, etc. |

|

2.Spout Delivery |

Base, Spout inlet section, feeding track, vibration disk, vibration feed out |

|

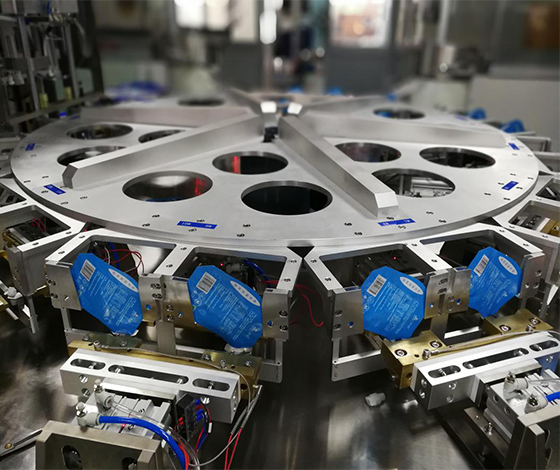

3. Turntable |

Main turntable, 12 groups station frames |

|

4. Station |

6 groups sealing cutting and finished & wasted products station |

|

5. Bag puttingplatform |

Magnetic Valve, active groups of cylinders, upper and down support board, support column |

|

6 .Automatically Placed bag system |

Cylinder, Guide rail, Bag collecting platform |

|

7. Regulator Panel |

Panel, regulating table, pressure regulating Valve |

|

PLC Section |

1.control method |

PLC |

|

2.Signal input |

1 .Photo-electricity switch, detection distance 0.1m 2. Magnetism switch 3. Temperature control signal output

|

|

|

3.signal output |

1. To control cylinder action by 24V relay controlling magnetic valve 2. To control 3 layer warning light by 24V relay |

|

|

Temperature control Section

|

1.control method |

PID |

|

2.Temperature sensor |

K type sensor |

|

|

3.Temperature accuracy |

±0.1℃ |

|

|

4.Heating facility |

300 mm Heating stick |

|

|

5.range |

Normal~350℃ |

|

|

Bag putting control |

1.Drive pattern |

PLC |

|

2.Drive Signal |

PLC I/O signal output |

|

|

3.Output control |

By 24V relay controlling magnetic valve to control cylinder action |

|

|

4.Protection system |

To turn/off photoeletric signal input by U-type switch to prevent cylinder breaking out |

|

|

Slitter turntable position |

1.Drive mode |

Converter drive |

|

2.Revolving speed |

0~60 Hz adjustable, positive and negative adjustable, accelerate /deceleration time adjustable |

|

|

3.Work Method |

For each rotation , photoelectricity switch to PLC, PLC drives magnetic valve |

|

|

Heat-sealing System |

Control method |

visual tuning indicator, Magnetism switch, Valve, slitter. Motor, gearbox, and central control system

|

|

Heat-sealing method |

Bi-directional sealing cutter for heat sealing , cylinder drive |

|

|

Temperature -sensing |

Thermocouple |

|

|

Thickness |

≤20 mm |

|

|

Spout delivery system |

Delivery spout |

Automatic feeder, rail |

|

Position control |

Optical sensor detection, the central control system |

|

|

Position sensor |

Photoelectric sensor |

|

|

Photoelectric sensitivity |

≤0.5 mm |

|

|

Bag delivery system |

Drive mode |

Cylinder drive |

|

Control mode |

Central control system |

|

|

Structural |

Duplex Sending Line |

|

|

Bag output system |

Drive mode |

Pneumatic Drive |

|

Control mode |

Automatic counting of the central control system, control pendulum edges, each slot 50-54 pcs |

|

|

Empty bag detection |

Photoelectric switch |

Our Service:

1. our engineer follow-up service for the door-to-door installation and training.

2. One Year warranty.

3. Warranty does not cover parts damaged by improper operation or maintenance procedures.

4. Warranty begins one date of receipt of equipment at customer’s facility.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar