Carbon dioxide transmission rate (COTR) is the measurement of the amount of carbon dioxide gas that passes through a substance over a given period. It is mostly carried out on non-porous materials, where the mode of transport is diffusion, but there are a growing number of applications where the transmission rate also depends on flow through apertures of some description.

Basically, the amount of permeability, diffusivity and solubility of CO2 through polymers were affected by temperature, pressure and film thickness. the amount of permeability and solubility were decreased by increasing film thickness but diffusivity was increased. However, by increasing temperature, permeability, solubility, and diffusivity were increased.

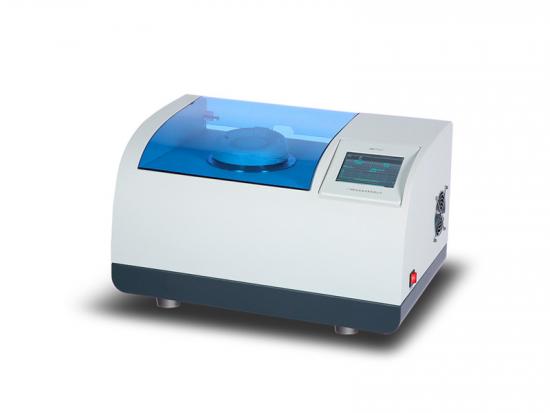

And how to test your packaging barrier film CO2 Transmission Rate? GBPI N500 and N530 Gas Permeability Tester can hlep you measrue your packaging material CO2 Transmission Rate.

Testing Standard comply to below ASTM Standard

ASTM D1434 - Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

ASTM F1115 - Standard Test Method for Determining the Carbon Dioxide Loss of Beverage Containers

ASTM F2476 - Test Method for the Determination of Carbon Dioxide Gas Transmission Rate (Co 2TR) Through Barrier Materials Using An Infrared Detector

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar