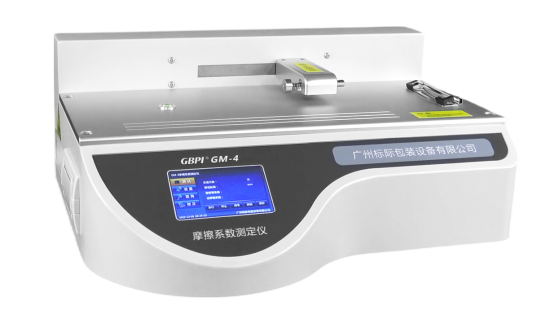

The Coefficient of Friction Tester is suitable for determining the static and dynamic friction coefficients of materials such as plastic films, composite films, aluminum foils, aluminized films, plates, rubber, and ceramics during sliding. By measuring the friction coefficient, it can accurately evaluate the slipperiness, ease of opening, and uniformity of films, thereby providing reliable guidance for production.

ASTM D1894

| Item |

Technical Parameters |

| Friction Coefficient Testing Range |

0.001~0.999 |

| Force Measurement Range |

0~10 N |

| Measurement Accuracy |

±0.5% FS |

| Slider Size |

63.5 mm × 63.5 mm |

| Slider Mass |

200 ± 2 g |

| Sliding Plane |

Stainless steel, 300 mm (length) × 150 mm (width) × 1 mm (thickness) |

| Workbench Size |

200 mm × 470 mm |

| LCD Display |

Test speed, dynamic friction coefficient, static friction coefficient |

| Stroke |

0~150 mm |

| Slider Movement Speed |

0~500 mm/min (stepless speed regulation) |

| Temperature Control |

Room temperature ~ 100℃ (optional) |

| Sample Thickness |

≤ 2 mm |

| Power Supply |

AC 220 V, 50 Hz |

| Dimensions |

470 mm × 300 mm × 300 mm |

| Weight |

13.6 kg |

- The force sensor is easy to calibrate: Quick calibration using a dedicated standard block, ensuring convenience and efficiency.

- The main unit is equipped with an LCD screen, which displays static and dynamic friction coefficients in real time.

- Optional heating function: Wide temperature control range from room temperature to 100℃, with adjustable temperature settings as needed.

- Supporting control software: Simple and clear interface, easy to operate.

- Displays real-time curves, which can be zoomed in or out.

- Sensor over-range automatic protection function and modular design for easy maintenance.

- The instrument is standard-equipped with a rigid sleeve, and springs can be switched for use, effectively preventing the stick-slip phenomenon of adhesive films.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar