- Plastic Films Heat Seal Tester With Five-point GBB-FView More

Heat Seal Tester is to test the temperature, pressure, and time for heat sealing of various film materials.

- Composite Film Heat Sealing Analyzer With ASTM F2029 Testing Standard GBB-AView More

GBB-A Heat Seal Tester accurately test the heat seal temperature range, heat seal strength, suitable heat seal speed and heat seal pressure of plastic film, flexible packaging composite film, coated paper, aluminum foil, etc. It is applied to the quality control of various plastic film, food and drug manufacturer, the scientific research and teaching experiment of testing institutions and schools

- BOPP Film Heat Seal Strength Analyzer GBB-A1

Heat Seal Analyzer widely used in industries of plastic films, food, pharmaceuticals, inspection agency, research institute and so on,it is to test the temperature, pressure, and time for heat sealing of various film materials.

- BOPP Film Heat Seal Tester

Tags :

- Flexible Barrier Materials Heat Seal Strength TestingView More

Heat Seal Tester apply to test the temperature, pressure, time and strength for heat sealing of various plastic films, composite film, aluminum foil and so on, widely used in industries of , food, pharmaceuticals, inspection agency, research institute and so on.

- Vertical Heat Seal Tester GBB-CView More

Product Introduction

GBB-C vertical heat seal tester can accurately measure the heat sealing temperature, heat sealing time, heat sealing pressure, and other heat sealing performance parameters of plastic packaging vertical bags, paper-plastic composite vertical bags and metal composite vertical bags(boxes). The heat sealing performance of samples of different materials are different. And the best heat sealing conditions can be accurately obtained through the determination of their heat sealing performance parameters.

Testing Principle

Put the sample on the lower tray of the instrument, adjust the appropriate height according to the size of the sample, set a certain sealing temperature, time and pressure as required, and start the instrument with one key. The fixture on the instrument will heat seal the sample according to the setting parameters. Under the manual state, step on the foot switch, and the heat sealing knife is pressed. The heat sealing time is determined by the value set by the time control. In the automatic state, the upper and lower heat sealing knives of the heat sealer will automatically heat seal repeatedly according to the set time.

Standards

ASTM F 2029

Specifications

Item Technical Parameters Temperature Range Room temperature ~ 250℃ Temperature Control Accuracy ±1℃ Hot Sealing Time 0.1s ~ 99.99 h Hot Sealing Pressure (0~1) MPa Hot Sealing Surface Upper and lower sealing knives: 300×5.5 mm, smooth; lower sealing bar with silicon pad Operation Mode Two modes: automatic and manual, with external cylinder Gas Source Compressed air Overall Dimensions 730(L) mm×400(B) mm×535(H) mm Weight 33.8kg Power 1200 W Power Supply AC 220V, 50Hz Characteristics

u High progress imported quality sensor, quality assurance

Original imported temperature sensor, wide temperature control range, high sensitivity, temperature control accuracy of ± 1 ℃, it has ultra-high stability and ultra-low failure rate.

u Independent control of heat sealing temperature

The rear of the heat sealing knife is equipped with a temperature sensor, and the temperature control of the inner and outer sealing knives is independent and set separately.

u Personalized test selection

Manual testing and automatic testing are free to choose. The automatic mode is time-saving and convenient, and the repeatability is fully automatic for heat-sealing the sample; the manual mode is equipped with a suitable foot switch, step on the foot switch, the heat sealing knife is pressed, and the safety protection is easy to operate.

u New air drive system

The drive system consists of a pressure gauge, a pressure regulating valve, and a cylinder. After the compressed air is introduced, the pressure is adjusted through the pressure valve, the air pressure can be accurately locked, and the heat sealing clamp is pneumatically driven, which is convenient and efficient.

u Wider range of customized services

The anti-sticking function of the heat sealing knife can be upgraded as needed, experience upgrade, and it is more intuitive and convenient to determine the best heat sealing conditions.

The shape, size and smoothness of the sealing knife heat cover can be customized to meet different scientific research needs.

Application

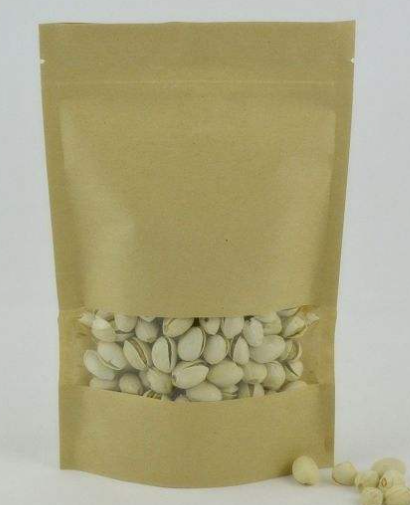

Plastic stand up pouch

Paper plastic stand up pouch

Aluminized stand up pouch

Milk Boxes

- Heat Seal Tester-GBB-F1

GBB-F1 Heat Seal Tester is to test the temperature, pressure, and time for heat sealing of various film materials. It is applied to quality inspection organizations, drug control institutions, research institutes, packaging, thin film, food companies, pharmaceutical enterprises, personal care industry and so on.

- ASTM F2029 Heat Sealability Test

- Laboratory Heat Seal Tester

- Heat Sealability Test for Flexible Barrier Materials

Tags :

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar