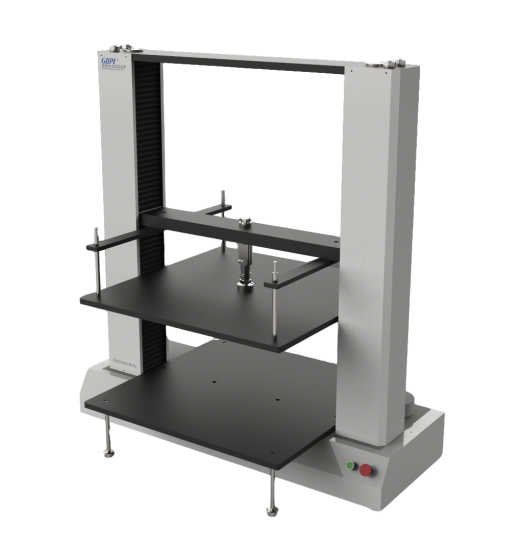

Universal material testing machine GHH

Universal material testing machine GHH

Product introduction

GHH universal material testing machine is theGuangzhou international r&d team based on GB, JIS, ASTM, DIN and other standards and market demand to upgrade the mechanical properties of new testing machine, suitable for all kinds of metal, non-metallic materials tensile, stripping, heat sealing, tearing, piercing, compression, bending and shear test, and then calculate the material parameters such as fracture strength, elastic modulus, It can also be used in the medical industry of syringe piston sliding, body tightness test verification.

GHH universal material testing machine has a flexible interface and control mode, can do stretching, peeling, and other tests, speed, thickness, clamping distance multi-parameter variable setting; The measuring accuracy can reach 0.5 level; The whole process is controlled by computer, open data structure; The core adopts imported parts, loaded with high-precision ball screw; Control measurement unit, can choose the built-in or external type, with perfect limit protection, overload protection, emergency stop and other safety protection functions.

GHH universal material testing machine is suitable for plastic sheet, pipe, profile, plastic film and rubber, wire and cable, steel, glass fiber and other materials of all kinds of physical and mechanical properties test for material development, is the physical property test, teaching research, quality control and other indispensable testing equipment.

Test principle

Will be clamped specimen in tensile machine fixture between two chuck, two clip do relative movement, through strength sensor and the machine is located in the moving clamp head built-in displacement sensor, collected test force value change and displacement in theprocess of change, to calculate the sample drawing (tensile strength, elongation at break and the elastic modulus of performance indicators, etc.

Standard

JJG 139, ASTM D828,ASTM E4, ASTM D882,ASTM D1938,ASTM D3330,ASTM F904,JIS P8113

Specification

Item

Technical Parameters

Measuring Force Range

0~3000 N (Multiple groups of sensors within 20000 N are available for selection)

Measuring Force Accuracy

Within ±0.5 %FS

Test Speed

0~500 mm/min (Stepless speed change)

Speed Accuracy

Within ±1% of the indicated value

Displacement Measurement Accuracy

Within ±0.5% of the indicated value

Effective Test Stroke

1000 mm

Elongation

1100%

Effective Test Width

30 mm

Force Value Resolution

0.001 N

Displacement Resolution

0.001 mm

Specification Dimensions

L×W×H: 750 mm×500 mm×1800 mm

Weight

150 kg

Power

600 W

Power Supply

AC 220 V, 50 Hz

Application

Plastic film

It is suitable for tensile, peeling, heat sealing, tearing, puncturing, compression, bending and other performance tests of plastic films, composite materials, flexible packaging materials, tapes and other products.

Composite film bag

It is suitable for tensile, peeling, heat sealing, tearing, puncture, compression, bending and other performance tests of composite films, co-extruded films, composite bags, retort bags, aluminum-plastic composite bags and other products.

Paper

It is suitable for tensile strength, peeling, deformation, tearing, heat sealing, bonding and other performance tests of paper, kraft paper, facial tissue, toilet paper and other products.

Medical Patches

It is suitable for tensile strength, peeling, deformation, tearing, heat sealing, bonding and other performance tests of medical cold compress, plaster and other products.

Pressure Sensitive Tapes

It is suitable for tensile strength, peeling, deformation, tearing, heat sealing, bonding and other performance tests of cellophane tape, electrical insulating tape, medical zinc oxide adhesive tape and other products.

Features

Flexibility and variety of control

Supports stretching, peeling, heat sealing, tearing, puncture, compression, bending, shear and other tests, speed, thickness, clamping distance variable parameters set, optional pneumatic fixture, suitable for a variety of fixtures.

High measurement accuracy

The test measurement accuracy can reach 0.5 level, high sampling rate (100 times/second), wide speed range, can adapt to high and low speed test, make the test data more accurate.

Imported core components, safe and reliable operation

Using high-precision ball screw loading, the loading is stable, the testing machine has a long life, good long-term stability and energy saving;

A plurality of load/deformation measurement subchannels are proposed, which support multiple sensor expansion measurement. A fully digital control system with imported AC servo system and motor can control the displacement zero flutters.

It has improved safety protection functions such as limit protection, overload protection, emergency stop, etc.

Double column table structure, good rigidity, control measurement unit can choose built-in type (simple appearance, save space) and external type (easy to upgrade, maintenance and separate from the microcomputer operation).

Intelligent operating system

According to the computer system design of the new version of GMP appendix, the test process parameters are flexibly set, and the function of audit tracing (test tracing, log tracing) is provided, which meets the requirements of data traceability and ensures the security and integrity of the test data. You can set different levels of system operation rights.

Intelligent Statistical analysis, support multiple data standard deviation analysis. At the same time, the system can be expanded, such as access to laboratory LIMS system.

Personalized test reports are set on demand to support multiple formats of data output.

Independent test can be separated from the computer, data can be processed automatically, and a built-in micro-printer can print data in real time. The instrument is equipped with computer interface, can also be connected to the computer online detection.

Laboratory intelligentIoT platform

It can be connected to the Internet of Things platform to realize digital network management:

Remote login to theIoT platform can be performed by directly accessing the software interface of the instrument.

All experimental data can be viewed anywhere by simply logging in to the platform;

Unified management of experimental data of all instruments in the interface of things platform can be achieved.

A complete laboratory management process can be realized;

One-click application for after-sales service, and one-click application for relevant accessories; After-sales staff can provide remote after-sales service through the system. There is a complete after-sales record on the platform, which is convenient for after-sales staff to provide high-quality online service;

Customers may download the required instrument materials, documents and operation videos on the platform by themselves.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar