I. Application

|

Plastic film |

Suitable for food, medicine, various types of composite films and other soft packages |

|

Medical nonwovens |

Medical Device Packaging |

II. Standards

ASTM F1921, ASTM F2029, GB/T 34445, QB/T 2358, YBB00122003

III. Working Principle

Align and overlap two test samples, clip one end in clips, two samples each spread over upper side and lower side of impact bar, and pass through the hot tack entrance; then the heat sealed two samples are pulled quickly to the impact bar, and forced off by the impact bar; the force value is the measuring value (unit: N).

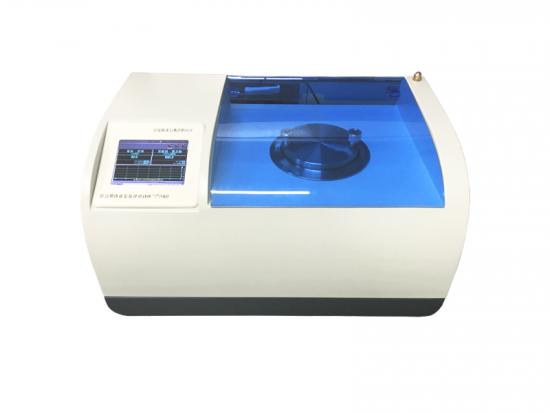

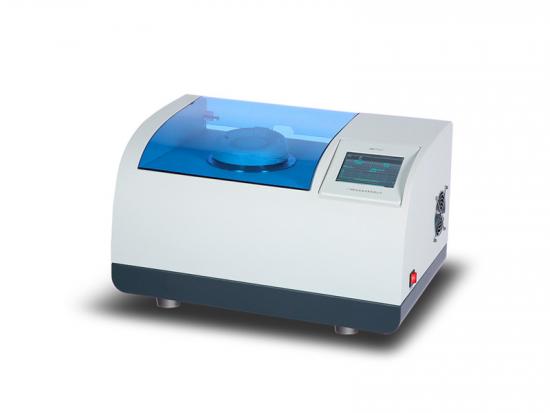

IV. Specifications

| Item | Technical Parameters |

| Temperature Range | Room temperature ~ 250℃ |

| Temperature Control Accuracy | ±1℃ |

| Heat Sealing Time | 0 ~ 99s |

| Heat Sealing Pressure | 0.1 ~ 0.8MPa |

| Sample Length | 200mm |

| Measuring Range | 0 ~ 300N |

| Overall Dimensions | 310×500×680mm |

| Power Supply | AC 220V, 50Hz |

| Power | 1100W |

| Weight | 45kg |

V. Features

1. P.I.D control system, high accuracy.

2. Upper and lower heat seal bars can set different temperatures.

3. LCD display, convenient and easy to use.

4. Built-in printer can print out report.

5. Can customize size, shape and smoothness of heat seal bar.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar