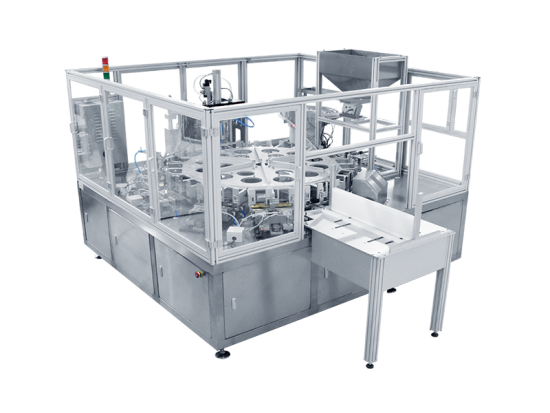

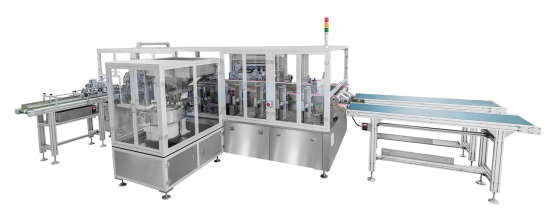

Working Principle

The spouts go through the hopper and the vibrating feeding tray to the ready position, and is pushed by the spouts to hang on the spouts bracket and rotate with the rotating disc to the pouch processing station. After taking the pouch and turning it over, the pouch to be processed is put on the pouch fixture on the spout (located directly above the spout holder), the pouch and the spouts are moved together with the turntable to the heat-sealing station for heat-sealing, and the front and rear heat-sealing knives are closed for heat-sealing treatment. The good pouch is pushed by the push-out mechanism to the finished bag storage section for storage. The untreated waste bags are automatically removed with the movement of the turntable to the waste bag rejection port.

Technical Specifications

| Item | Technical Parameters |

| Overall Dimensions | 2400 x 2200 x 2000 mm (Length x Width x Height) |

| Packaging Types | Stand-up Pouches, 3-Side Seal Pouches, Gusseted Bags, Special-Shaped Bags |

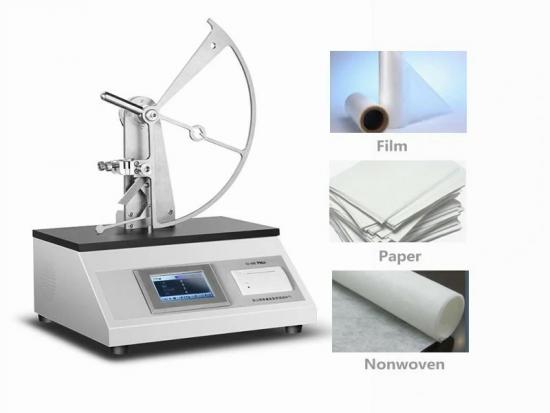

| Material Types | Pouches: Inner Layer PE, Inner Layer PP |

| Tubes: PE, PP | |

| Product Specifications | Bag Length: 80~190 mm (L), 70~120 mm (W) |

| Sealing Length: 60~120 mm | |

| Straw Sizes: 8.5 mm, 10 mm, 14 mm, 16 mm, etc. | |

| Working Speed | 80-90 pcs/min |

| Positioning Accuracy | ≤0.5 mm |

| Sealing Tools | Total 6 groups: 1 Preheating, 4 Heat-Sealing, 1 Cooling |

| Temperature Control Modules | 18 groups, Accuracy ±0.1℃ |

| Heating Temperature | 0~300℃ |

| Power Supply | 380V/50Hz, 11KW |

| Air Supply | 0.6~0.8MPa, 2000L/H |

| Equipment Weight | 2100 Kg |

Application Field

|

|

|

|

Jelly spout bag |

Soy milk spout bag |

Toiletries spout bag |

|

|

|

|

Puree bag |

Special-shaped nozzle bag |

Folding outdoor hydration bag |

GBPI Spout Sealing Machine Adopt Advanced System

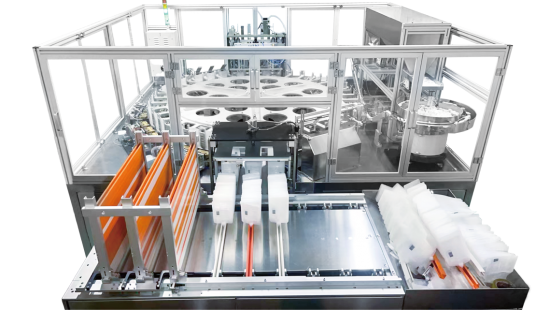

♦ Spout Sealing Machineconsists of spout delivery system, bag delivery system, heat sealing system, bag collecting system, central control system and base.

♦ The spout delivery system consists of chutes, vibrating disks and lead rails. The photoelectric sensors can induce the spouts to control the charging action.

♦ The bag delivery system utilizes the pneumatic sucker.The delivery and sealing system have double positions, which doubls the efficiency.

♦ The heat sealing system includes a big turntable, heat sealing blades and workstations. There are 6 sets of heat sealing blades: 1set for preheating, 4 for heat sealing and 1for cooling.

♦ The workstations are adjustable for bags of different sizes. Customers can order diverse sealing blades for spouts of various types.

♦ Every sealing blade has an independent temperature controller,and runs and debugs independently.

♦ The bag collecting system consists of finished products collecting table and waste product recycling table. Photoelectricity sensor and pneumatic control makes the manufacturing process truly automatic.

♦ The control panel deploys a touch screen, on which all kinds of parameters can be set, and working status in real time such as complete amount, time, success rate and failure rate can be show.

♦ Other parts: 12 temperature control meter, 18 pressure gages, and 2~4 emergency stop buttons (1 button on each side of the machine).

♦ The base is easy to dismantle, transport and assemble.

1. Fully automatic; a single set of machine needs only one operator, and the operator just needs to load enough spouts and bags at intervals.

2. Adopting round disc structure, the equipment occupies small space.

3. All the components are made of aluminum and stainless steel, and meet the hygienic and quality requirements of food, pharmaceutical, environmental and industries.

4. Easy to use with precise control; runs stably and works long hours continuously.

5. Adopts imported temperature control module, SMC pneumatic component, Omron PLC control unit to insure the quality, performance, and life of the machine.

6. Automatically detects faults, gives alarms, stops, diagnoses and show where the fault is.

Main Components and Their Brands

|

No. |

Name |

Brand |

|

1 |

Servo motor |

Made in China |

|

2 |

Frequency transformer |

Omron |

|

3 |

PLC |

Omron |

|

4 |

Magnetic switch |

SMC |

|

5 |

Photoelectric switch |

KEYENCE/Omron |

|

6 |

Pneumatic component |

SMC/AIRTAC |

|

7 |

Temperature control module |

Omron |

|

8 |

Splitter |

DEX |

|

9 |

LCD touch screen |

Omron |

Configuration

|

No. |

Name |

Quantity |

|

1 |

Spout sealing machine |

1 set |

|

2 |

Vibrating disk |

2 sets |

|

3 |

Sealing blade |

6 sets |

|

4 |

Bag putting rack |

1 set |

|

5 |

Bag collecting rack |

1 set |

|

6 |

Installation tools |

1 set |

|

7 |

Spefication (User Manual) |

1 set |

Machine Production Working Samples

GF1600-BSpout Sealing Machineis a fully automatic system consists of heat sealing system, spout input system, and bag input system, bag output system, and central control system mounted on single base frame from module. All systems are equipped with electronic sensors and relays to work cordially for efficient and quality manufacturing of packaging bags.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar