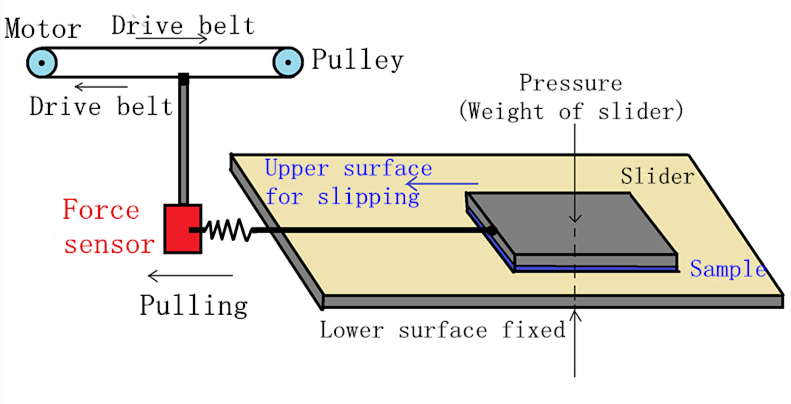

Test Principle

Use a clamp to clamp the strip test sample, and wrap the slider with the sample to be tested, and then place the slider on the hanging hole of the sensor. Under a certain contact pressure, the conveyor belt is driven by the motor to move the force sensor. , that is, to move the two test surfaces relative to each other. The force signal measured by the force sensor is amplified by the integrator and sent to the recorder, and the kinetic friction coefficient and the static friction coefficient are recorded respectively.

Standard

ISO 8295、ASTM D1894、TAPPI T816

Specification

|

Item |

Technical parameter |

|

COF test range |

0.001~0.999 |

|

Force range |

0~10 N |

|

Measurement accuracy |

±2% FS |

|

Slider size |

63.5 mm×63.5 mm |

|

Slider mass |

200±2g |

|

Workbench surface size |

200 mm×470 mm |

|

LCD display

|

Test speed, dynamic friction coefficient and static friction coefficient |

|

Stroke |

0~150 mm |

|

Slider movement speed |

0~500 mm/min (Support stepless speed regulation) |

|

Sample thickness |

≤2 mm |

|

Power supply |

AC 220 V, 50 Hz |

|

Dimensions |

470 mm×300 mm×300 mm |

|

Weight |

13.6 kg |

Feature

Instrument is stable, reliable and easy to maintain

The force sensor is easy to calibrate, using a special standard block to quickly calibrate, which is convenient and fast; the host with a LCD display, which displays the static friction coefficient and kinetic friction coefficient in real time; the supporting control software, the interface is simple and clear, easy to operate; display real-time scalable curves; Scope automatic protection function, functional modular design, easy maintenance.

Intelligent operating system

According to the new VERSION of GMP appendix computer system design, test process parameters are set flexibly, with audit tracking function (test tracking, log tracking), to meet the requirements of data traceability, to ensure the safety and integrity of test data.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar