1. Standards

ASTM D642, ASTM D4169, TAPPI T804, ISO 2872, ISO 12048, JIS Z0212, GB/T 16491, GB 4857.4

2. Specifications

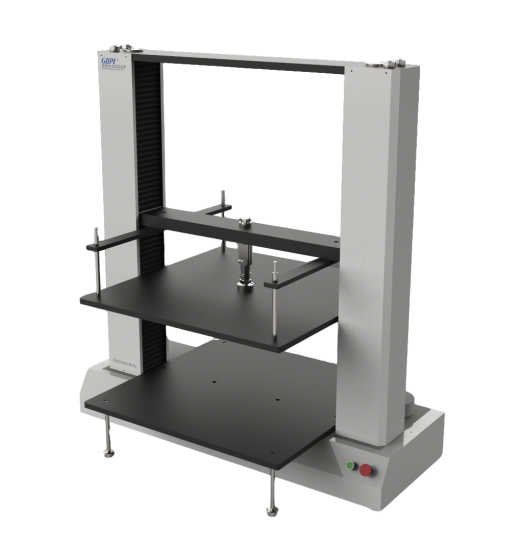

|

Test range |

0~3000N |

|

Test speed |

0~300mm/min(infinitely variable speeds) |

|

Test distance |

0-185mm |

|

Valid working area |

480x390mm |

|

Instrument size |

550x460x860mm |

|

Weight |

120Kg |

|

Power supply |

AC 220V, 50Hz |

3.Application

|

|

Pressure resistance |

It is suitable for pressure resistance testing of various packaging bags. |

|

Burst resistance |

It is suitable for burst strength testing of various packaging bags. |

4. Features

1. Fully functional, multiple parameters setting and test.

2. Wholly automatic, can set auto judgment, auto return and stop; auto process data.

3. Built-in operation system can test independently without computer.

4. LCD display test data.

5. Can set fixed speed and measure the force.

6. Can set fixed pressure and measure displacement.

7. Professional software, simple interface, easy to operate.

8. Display multiple curves; can zoom and move curves freely.

9. Professional test report, can edit and export file in Excel, PDF format etc.

10. Simple calibration of force sensor.

info@gbtest.cn

info@gbtest.cn

en

en ru

ru es

es ar

ar